Voltiris and the Delphy Improvement Centre in the Netherlands have completed a one-year trial examining the effects of Voltiris' spectrally filtering solar panels on sweet pepper production. The study showed an increase of 1.4 kg per square metre (+9%) in Class I fruit yield, while leaf temperatures under the panels were up to 4°C lower during summer conditions. Further research is required to better interpret the observed differences and their longer-term implications.

© Voltiris

© Voltiris

The trial was conducted at the Delphy Improvement Centre using spectrally filtering photovoltaic modules installed above a sweet pepper crop. The technology separates incoming light by frequency: photosynthetically active radiation (PAR) needed for crop growth is transmitted, while other radiation, including a large proportion of heat radiation, is reflected towards solar cells and converted into electricity.

The experiment was carried out with the sweet pepper variety Alzamora. A total of 48 Voltiris modules were installed in a 250 m² greenhouse compartment. Results were compared with a parallel reference trial using the same variety and planting date, but without the solar modules.

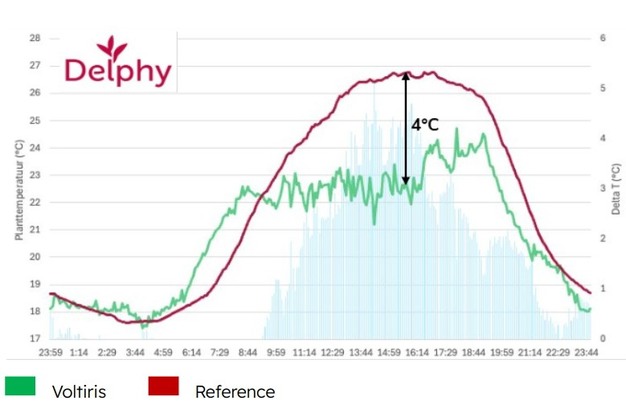

Clear impact on plant temperature

Under the Voltiris modules, plant temperature was consistently lower during sunny periods, with differences of up to 4–5°C. This reduction is a direct result of the spectral filters, which intercept part of the radiative heat and convert it into renewable energy. The cooling effect occurred only under direct sunlight; as a result, winter heating demand remained unchanged.

The lower leaf temperature may have slightly moderated crop development and plant load early in the season, contributing to a more vital crop later on. In the reference compartment, crop health declined towards the end of the season, resulting in smaller fruit size and an earlier end to the harvest period.

© Voltiris

© Voltiris

During the trial, the climate strategy in the compartment with Voltiris modules was kept identical to that of the reference compartment. Based on the current insights into the impact on plant temperature, further optimisation appears possible. As crop advisor Jeroen Zwinkels (Delphy) explains: "Because the Voltiris system lowers plant temperature, we could have set a higher ventilation temperature. This would have resulted in less vent opening and higher CO₂ levels. We could also have used the energy screen less intensively than usual, allowing more light to enter."

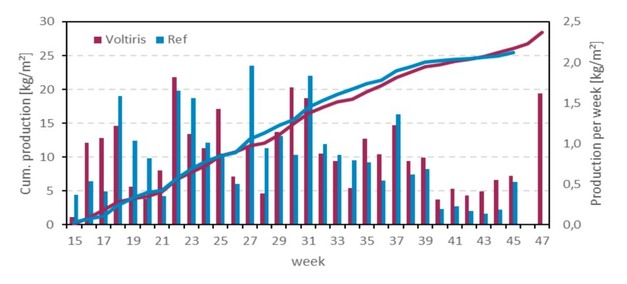

Production

The greenhouse compartment equipped with Voltiris modules achieved a Class I yield of 27.7 kg/m², compared with 25.4 kg/m² in the reference, representing an increase of 9%.

© Voltiris

© Voltiris

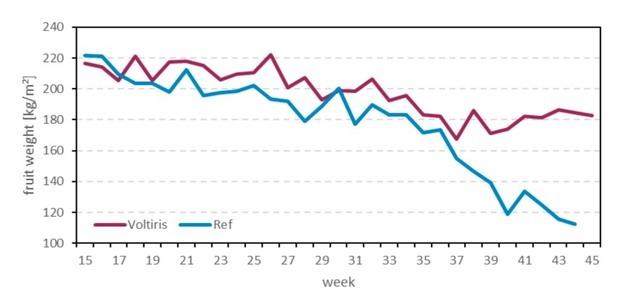

Fruits grown under the spectral filters were heavier on average. The higher individual fruit weight, combined with a longer harvest period, contributed to the overall yield increase.

© Voltiris

© Voltiris

In the reference compartment, challenges with plant health emerged during the final months of the crop cycle. The high plant load earlier in the season may have negatively affected crop vitality in this compartment. As plant health declined, average fruit weight decreased and harvesting ended two weeks earlier than in the compartment with Voltiris panels. Over the full trial period, 13% of the fruits in the reference were rejected due to insufficient weight, compared with only 5% under the Voltiris modules.

It could not be conclusively determined within this study whether the lower leaf temperature in the Voltiris-equipped greenhouse led directly to the more vital crop, or whether this explains the production differences observed. The researchers assume that the Voltiris panels reduced heat stress and may also have contributed to more balanced growth early in the season. However, drawing firm conclusions on this relationship requires further research.

Energy production

Energy output from the trial was measured, but due to strong edge effects within the experimental compartment, the results were not considered representative of commercial practice. For this reason, energy production is being monitored at commercial sites, including TomatoMasters in Belgium and Meier Gemüse in Switzerland. Data from these locations support Voltiris' expectation that approximately 325 MWh per hectare can be generated under Dutch conditions.

Business case

The financial feasibility of the system was not included in the Delphy study. Voltiris is independently developing business cases for different crops and regions. Calculations based on energy production, electricity prices, added crop value and available subsidies indicate payback periods of five to seven years, assuming a minimum installation size of one hectare.

Next steps

The trial provides a promising outlook for the productive integration of solar technology in greenhouse horticulture. Further research is needed to substantiate these results, preferably under full commercial operating conditions. As part of this follow-up, Delphy Improvement Centre is evaluating the Voltiris modules in strawberry, a crop that benefits from high light levels but is sensitive to excessive heat.

As a next step in commercial deployment, Voltiris has completed its first one-hectare installation at Meier Gemüse in Switzerland, where nearly 2,000 modules were installed in collaboration with Horconex.

For more information:

For more information:

Voltiris

[email protected]

www.voltiris.com