Growing phytosanitary pressure, intensive crop rotation and the rising unit value of seeds are forcing horticultural nurseries to further refine their seeding and grafting processes. In greenhouse crops such as tomato and watermelon, the use of rootstocks has become an established technical tool to provide vigour and resistance to commercial varieties, while at the same time increasing the demands placed on process quality and repeatability.

To improve the efficiency of these seeding and grafting operations, which are essential to launching each production cycle, Smart Sowing, a company specialising in the manufacture of seeding and grafting solutions for professional nurseries, offers its equipment to the sector, with machines now operating on every continent.

© Smart Sowing

© Smart Sowing

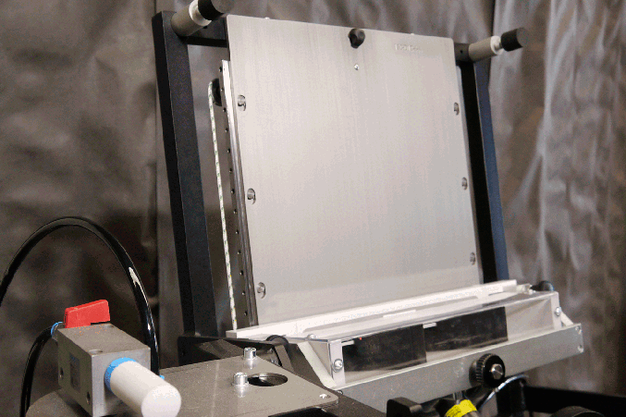

"Within our range, the semi automatic grafting machine stands out, designed for nurseries that require a high level of process control without necessarily resorting to fully automated systems," explains Francesc Carrete from Essen.

"It is a machine where the operator places the rootstock and the variety, the machine performs the cut and applies the clip. It is a compact solution that can be easily integrated into nursery facilities, where labour and final graft quality remain critically important," says Francesc. "This type of technology allows the process to be repeated uniformly, maintaining consistent graft quality, which is particularly relevant in high value production."

One of the key differentiating factors of the company, owner of the Conic System brand and with more than 35 years of experience in horticultural machinery, is its Decop technology and its plate based seeding systems.

© Smart Sowing

© Smart Sowing

"It is the most precise system for any type of seed, as our calibrated combs ensure uniform dosing even with flat or irregular seeds, both with bare seed and with high value coated seed."

Precision becomes especially critical when working with hybrid seeds or premium varieties, "whose cost can reach values close to one euro per unit." "The single head system, known as Decop, a term that in Catalan means 'in one stroke', allows the entire tray to be sown at once, adapting the configuration of the seeding line to each customer's production needs."

More than 35 years of seeding experience

The origins of Conic System are directly linked to nursery operations. The first machine was developed in house for a nursery in Barcelona, at the request of someone close to the company, and its success led to the start of manufacturing seeding equipment for third parties.

"Today, Smart Sowing solutions are used both in small nurseries and in large companies in the sector, thanks to their modular configurations, which make it possible to adapt capacity and work rate to the size of any business."

© Smart Sowing

© Smart Sowing

"The company has operational equipment in very diverse markets, literally around the world, from Japan to California, including Europe, Africa, Latin America and the Middle and Far East. Recently I was in Colombia visiting clients and found a nursery still working with one of our machines that is over 35 years old," he says. "They told me it was working with the same efficiency as when they bought it."

"This operational longevity reflects the robustness of our machines, demonstrates the reliability of our equipment, and makes us very proud to have created dependable, durable seeding and grafting solutions, and above all, ones built around an efficient technology, the Decop system," he concludes.

For more information, please contact us:

Smart Sowing

Avda. Olof Palme 10, 08440 Viladecans

Barcelona(SPAIN)

T. +34 936 096 837

[email protected]

https://www.smartsowing.com