JB Groep has introduced a fully redesigned line of ultrafiltration (UF) systems for the greenhouse horticulture sector. The new range is based on operational experience from around 50 UF installations worldwide, combined with recent technological developments. Drawing on these insights, the company has thoroughly reviewed and optimized the system design.

According to Chris van Hulzen, CTO at JB Groep, the new UF models provide improved membrane conditioning. "The result is a very stable and consistently high disinfection performance over an extended period, with minimal use of chemicals," he says. "This means the systems align well with the needs of modern growers and installers: using water sustainably without compromising operational reliability or crop quality."

"With this new generation of UF units, we combine maximum safety and stability with minimal environmental impact," says Chris. "We see a strong increase in demand for reliable, low-chemical water treatment. With our solutions, growers and installers can confidently take the next step in their water strategy."

© JB Groep

© JB Groep

Wide applicability and proven disinfection performance

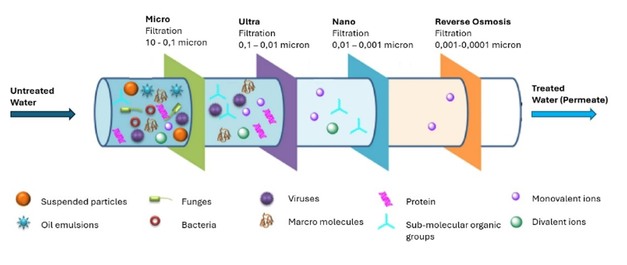

Ultrafiltration can be used to treat a wide range of water sources, including surface water, river water, rainwater and recirculation water, and it can also serve as pre-filtration for reverse osmosis systems.

The new UF systems operate according to the so-called "gatekeeper" principle, the CTO explains. "Micro-organisms simply cannot pass through our 0.02-micron membranes."

- Disinfection of:

- Fungi (1–30 micron)

- Bacteria (0,2–1 micron)

- Viruses (0,08–0,12 micron) - Removal rate:

- Fungi/Bacteria: LOG 6 (99,9999%)

- Viruses: LOG 4 (99,99%)

© JB Groep

© JB Groep

All membranes used are PFAS-free, in line with increasingly stringent environmental regulations.

Stable water quality, less chemicals, lower energy costs

The new UF units are not affected by the light transmittance (T10 value) of the water. "Discoloration caused by iron or cocopeat therefore does not limit the disinfection capacity."

He adds that the systems offer several important practical benefits. Nutrient values are retained after disinfection, the pH of treated water remains more stable, and energy consumption is up to around 70% lower compared with other disinfection technologies. In addition, the technology enables a closed water system with maximum recirculation.

By filtering particles down to 0.02 microns, the UF units create a much cleaner irrigation system—up to 1,000 to 4,000 times cleaner than traditional disinfection methods, according to Chris. As a result, fewer chemical agents such as hydrogen peroxide are needed to keep pipework clean. Organic contamination is removed from the water, preventing it from serving as a breeding ground for new infections.

Flexible capacity for every installation

With unit capacities ranging from 50 to 800 m³ per day, JB Groep offers a suitable UF solution for virtually every application, according to Chris. "If higher capacities are required, this can easily be achieved by combining multiple units, which further increases operational reliability."

JB Groep's systems can be used as standalone units or fully integrated with the climate computer. This offers several advantages, including user-friendly operation via a touchscreen, remote monitoring and control through secure cloud-based systems, and optimal integration into both new and existing installations.

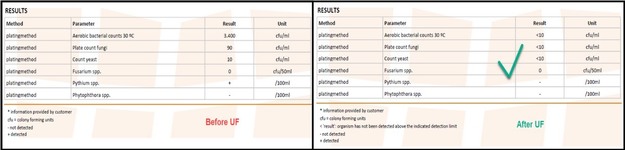

Successful field trials and strong market demand

"The first new models have been extensively tested using both drain water and surface water, and they completed these practical trials with perfect results," Chris explains. "Demand for the new UF units is strong, from both growers and installers who are looking for a controlled, clean and future-proof solution for water treatment."

© JB Groep

© JB Groep

"Together with the installer, we assess the customer's entire water system," he adds. "This ensures that the ultrafiltration system not only performs optimally from a technical perspective, but also integrates seamlessly into the grower's water system and day-to-day operations."

For more information:

Chris van Hulzen (CTO)

JB Groep

+31 6-28190208

[email protected]

www.jbgroep.nl