Ask several greenhouse growers what the "best" LED lighting system is, and the answers will vary. Some will focus on efficiency figures, others on upfront investment, and others on brand familiarity or existing installations. As LED lighting has become standard practice in commercial greenhouses, it has become clear that the question itself is changing. The best commercial greenhouse LED lighting system, according to Abhay Thosar of Sollum Technologies is one that adapts spectrum, intensity, and Daily Light Integral (DLI) in real time to crop requirements, seasonal light availability, and energy conditions.

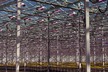

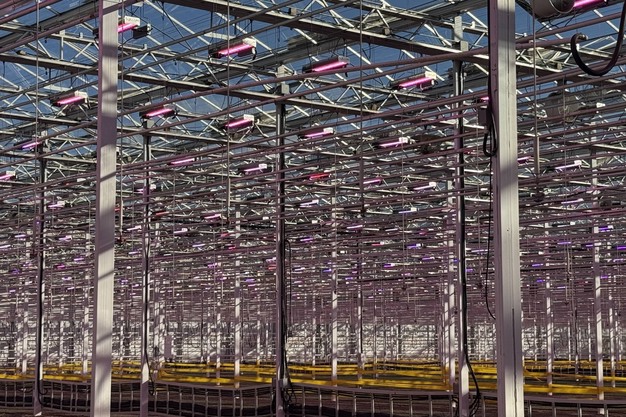

© Sollum Technologies

© Sollum Technologies

Energy costs continue to fluctuate, while natural light availability varies throughout the year. "At the same time, growers are expected to deliver consistent quality, predictable yields, and stable production planning. LEDs are no longer a differentiating technology but part of the baseline infrastructure. What separates lighting strategies is not what appears on a specification sheet, but how a system performs under real greenhouse operating conditions", he says. "Greenhouse production is inherently variable. Lighting systems need to respond to those changes rather than operate as static installations."

When LED fixtures are compared, the evaluation often centers on efficiency in µmol/J, maximum light output, purchase price, and warranty terms. While these metrics are useful, they do not fully reflect how a lighting system functions once installed. Seasonal and daily changes in sunlight, differences between zones within the same greenhouse, crop-specific responses to spectrum and intensity, and shifting energy tariffs all influence real-world performance.

"A fixture that looks optimal on paper may become restrictive if it cannot adapt as conditions evolve," Abhay explains. "Adaptability is part of performance."

Modern commercial greenhouse LED systems are increasingly defined by their ability to adjust over time. Spectrum flexibility allows growers to modify light quality depending on crop type, growth stage, and production objectives. Adjustments such as increasing blue light during early growth stages or introducing far-red light during low-light periods are examples of how spectral control can be used to influence plant responses.

"Flexible spectrum gives growers the ability to align lighting with plant behavior, response rather than treating light as a fixed input," says Abhay.

Control over light intensity is another factor. Rather than maintaining constant output for long periods, adjustable intensity allows growers to respond to variations in natural light and avoid unnecessary energy use. This approach is closely linked to DLI-based control, where lighting decisions are guided by the total amount of light a crop receives each day. In advanced systems, DLI targets are reached through automated modulation of light output as sunlight conditions change throughout the day.

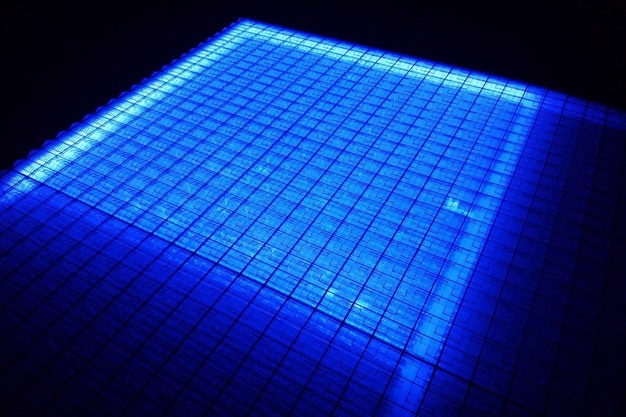

© Sollum Technologies "The objective is to manage consistent DLI accurately without adding complexity to daily operations," Abhay notes.

© Sollum Technologies "The objective is to manage consistent DLI accurately without adding complexity to daily operations," Abhay notes.

Greenhouse environments are rarely uniform, which makes zone-level control relevant. Differences in structure, orientation, or crop layout can lead to varying light requirements within the same facility. Lighting systems that allow adjustments by zone support more consistent crop development across the greenhouse.

Integration with existing greenhouse systems is another consideration. Lighting interacts with climate control, energy management, and crop planning, and systems that operate within this broader framework are easier to manage over time. Long-term adaptability also plays a role, as lighting strategies often change in response to new cultivars, market demands, or energy conditions. Systems that support these changes without requiring full replacement offer greater operational flexibility.

Many greenhouse LED installations still rely on static schedules, where light recipes are set after installation and adjusted manually, if at all. Dynamic lighting strategies take a different approach by continuously adapting spectrum, intensity, and timing to crop needs, available daylight, seasonal patterns, and operational constraints. These adjustments can be made in real time and at zone level, with the system managing the underlying complexity.

"The system handles the variability, so the grower can focus on crop outcomes," Abhay says.

In practical terms, the most suitable commercial greenhouse LED systems support consistent crop performance across seasons, improved uniformity, and predictable production results. They allow growers to adjust lighting strategies without replacing hardware and to manage energy use in relation to production goals. In this context, "best" is less about the most powerful fixture and more about a system's ability to adapt as conditions change.

"The relevant question for growers is no longer which LED system is the best in absolute terms, but which system provides the control and flexibility needed to respond to changing conditions, plant requirements at each growth stage, and long-term operational objectives. Greenhouses are dynamic environments, and lighting systems are increasingly expected to function in the same way."

For more information: Sollum Technologies

Sollum Technologies

sollumtechnologies.com