In commercial greenhouse and vertical farming systems, productivity and cost efficiency depend not only on climate control and lighting, but also on how effectively plant physiology is managed. One often overlooked factor is the balance between root development and canopy growth, which directly influences crop cycle length, resource use, and annual yield.

According to Nir Tahan, Founder, CEO and Head Consultant at Tahan, maximizing root mass is rarely the objective.

"The goal is not to grow the biggest root system possible," he explains. "Roots should support fast, uniform leaf growth, not consume resources at the expense of the foliage."

© Tahan

© Tahan

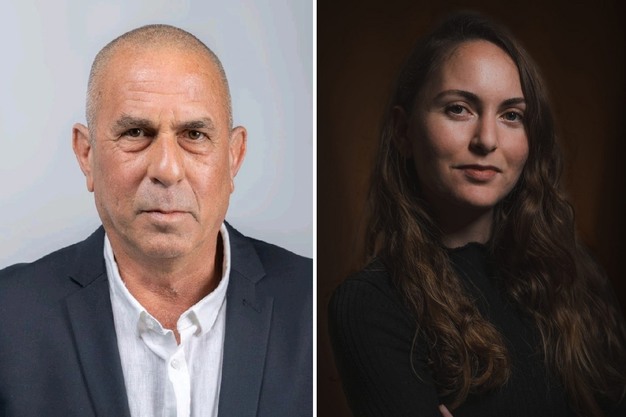

Nir Tahan and his daughter, Noa Tahan. Noa is in charge of business development for the company

Agronomic consulting focused on return on investment

Tahan's consultancy builds on years of international experience as a farm owner and leading agronomist on projects worldwide. Recently, his daughter, Noa Tahan, joined the company as Business Development and Social Manager. The company works both with existing farms seeking performance improvements and with new projects developed through a collaborative, non-turnkey model.

A key component is a detailed feasibility study. "We break down energy use, labor time, and system operation to understand the real cost of producing one kilogram of lettuce. Only then can growers make informed decisions."

© Tahan

© Tahan

Root–zone size: Efficiency over volume

Large, dense root systems are often seen as a sign of plant health, but Nir challenges this assumption.

"An oversized root system uses more water and fertilizer without increasing yield," he says. "In many cases, it slows canopy development."

Images shared by Nir of young lettuce plants show rapid biomass accumulation above ground with relatively modest root mass. This principle applies across NFT and substrate-based systems.

"The system type doesn't change plant physiology," he explains. "What matters is how the root zone is managed."

© Tahan

© Tahan

Climate control drives root–to–foliage balance

Stable and optimal growing conditions are key to rapid canopy development and an efficient root system. Temperature, humidity, VPD, light intensity, and a precise nutrient interface aligned with plant demand must remain within optimal ranges throughout the entire growth cycle.

"The greenhouse must provide optimal conditions 365 days a year," he says. Even in hot regions such as the Gulf states, he notes, short periods of heating in winter and even the use of artificial lighting may be required.

"It only takes two to three cold nights or a few cloudy days to slow growth enough to disrupt supply commitments," he explains.

Similarly, supplemental lighting during cloudy periods can prevent delays in reaching target weights.

In the production of millions of plants per year, every gram counts. In crops with short growth cycles, every day in which the plant does not perform at its full potential has a direct impact on reaching the target weight. For example, in a crop of one million heads, a deviation of just one gram per head, above or below the target weight, translates into a total difference of one million grams, equivalent to 1,000 kg of produce, representing a significant profit or loss.

© Tahan

© Tahan

Precision in irrigation and nutrition

In hydroponic systems, continuous irrigation shifts the focus to nutrient composition and EC management.

"The elements are the same worldwide. The difference is in the ratios, and those ratios strongly influence how much biomass goes into roots versus leaves."

Balanced nutrient strategies encourage efficient root systems while supporting rapid foliar growth. "The objective is not to restrict roots, but to avoid unnecessary root expansion."

© Tahan

© Tahan

Rethinking the nursery phase

One common mistake is transplanting seedlings too early.

"Keeping seedlings in the nursery longer often improves overall performance. A well-developed seedling resumes growth immediately after transplant."

He recommends approximately 20–23 days in the nursery, depending on cell size, allowing roots to fill the plug without becoming constrained.

There is also a clear economic benefit. "Plant density in the nursery is several times higher than in the growing area," he notes. "Extending nursery time can reduce the size and cost of the production zone."

Yield, cycle time, and economics

Most commercial lettuce programs target head weights between 120 and 150 grams. The average cycle time (winter and summer) is around 26 days, allowing up to 14 cycles per year.

"Under optimal growing conditions and precise nutritional management, reaching 150 grams can take only 14 to 15 days after transplanting. Of course, the choice of high-quality varieties also affects plant performance," he says.

This dramatically increases annual yields. "In many regions, farms produce around 50 to 55 kilograms per square meter per year. With optimal root-to-canopy management, more than 100 kilograms per square meter is realistic."

Because fixed costs remain constant, higher output reduces unit costs. "Climate control systems operate whether you harvest 100 or 200 heads of lettuce. Producing more within the same infrastructure lowers the cost per head."

As climate change increasingly affects open-field production and uncontrolled greenhouses, Nir sees controlled environment agriculture as a critical buffer. "We hear more and more about farms announcing closures due to economic difficulties. The Controlled Environment Agriculture (CEA) industry needs to take a close look at itself, make adjustments accordingly, and change its mindset. This applies to both horizontal and vertical farms.

"Greenhouses that truly control all conditions will be both profitable and the most reliable suppliers," he concludes.

"Higher yields are possible if growers are willing to challenge established methods and focus on efficiency rather than tradition."

For more information:

Tahan Smart Farming

Nir Tahan, Founder

[email protected]

Noa Tahan, Business Development

[email protected]

https://tahan-smart.com