Over the past year, horticultural lighting has changed significantly, with growers, researchers, and technology suppliers pushing the boundaries of what LEDs and intelligent controls can deliver. From tackling moisture management challenges during high-intensity winter lighting to the rise of AI-driven and wireless systems that fine-tune spectra and power use in real time, the industry has accelerated toward smarter, more efficient, and more adaptive solutions.

Players like RED Horticulture, Heliospectra, P.L. Light Systems, Sollum Technologies, Cosmicnode, Philips, and Signify have marked milestones, entered partnerships, and introduced innovations that highlight a sector shifting quickly from simple illumination to fully integrated, data-led cultivation strategies.

© Mechatronix

© Mechatronix

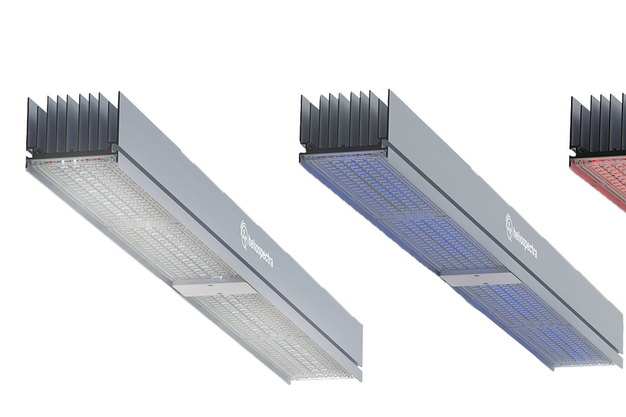

Heliospectra AB is marking the 10th anniversary of its helioCORE control system, and 15 years as a dynamic lighting supplier. Founded in 2006 as a research-focused company, Heliospectra brings almost two decades of expertise in utilizing, designing, and producing smart LED lighting and control systems.