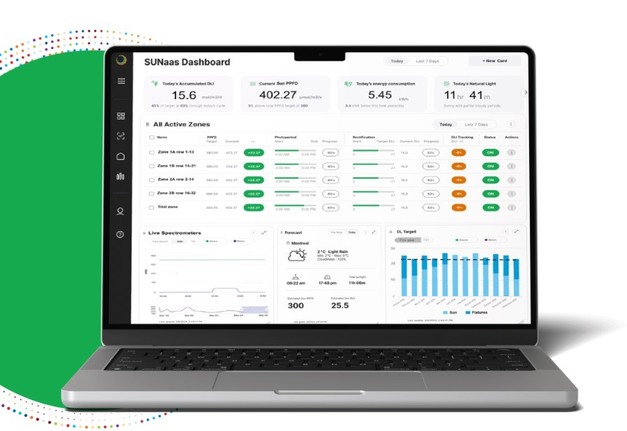

Static LED improves efficiency over HPS, but it locks growers into fixed spectra and schedules. Sollum's advanced dynamic LED grow light solution, powered by SUN as a Service® (SUNaaS® ), adjusts spectrum, intensity, and timing in real time to keep DLI on target, and match crop stage.

What changes when you go advanced dynamic

When growers switch to advanced dynamic lighting, several things change. DLI becomes reliable because adaptive control avoids under or over lighting as weather shifts, and growers can tailor zone-by-zone recipes and management. Energy use becomes tariff aware, with real-time optimization that can lower cost per kilogram. Total energy savings can reach up to 40 percent compared with HPS when combining LED efficiency with additional gains over standard LED.

© Sollum Technologies

© Sollum Technologies

Crop outcomes improve as dynamic spectrum and intensity are matched to growth stage and cultivar needs. Programs in tomatoes, cucumbers, and lettuce have shown increases in both yield and quality. Operations become more resilient with unlimited zones, a full recipe library, and integration with existing climate control systems.

Proof that matters

Growers have seen proof in real operations. Tomatoes showed a 19.5 percent yield increase with an adaptive spectrum strategy compared with static LED lighting. Mini cucumbers gained an average of 16.7 percent after moving from static LEDs. Winter pepper production in Canada has demonstrated clear feasibility and strong quality under dynamic LEDs. Leafy green programs have shown better appearance, texture, and stage-specific results using cultivar-specific dynamic recipes.

© Sollum Technologies

© Sollum Technologies

Energy and economics

Energy performance and economics follow the same trend. LEDs can save up to 40 percent compared with HPS, and Sollum's dynamic optimization can add up to 16.8 percent additional efficiency over standard LED. SUNaaS enables zone control, a custom light-library, and smooth integration with existing climate systems through standard protocols.

© Sollum Technologies

© Sollum Technologies

Implementation

The implementation roadmap is straightforward: assessment, followed by design and zoning, commissioning on SUNaaS, proof of value with shared KPIs such as yield, DLI adherence, energy per kilogram, and quality, then scaling and ongoing optimization.

For more information: Sollum Technologies

Sollum Technologies

Email:[email protected]

sollumtechnologies.com