As more greenhouse and indoor cultivators embrace LED lighting, dynamic spectrum fixtures are gaining momentum. But with their rising popularity comes confusion: what does "dynamic spectrum" actually mean?

According to Henry Berman, Chief Customer Engagement Officer of Scynce LED and an early advocate for tunable LED light technology, not all dynamic spectrum fixtures are created equal, and understanding the features beyond the spec sheet is essential.

"It's exciting to see dynamic spectrum gaining traction," he says. "But growers need to understand how these systems actually function and how those functions translate into tangible revenue (i.e., higher quality, higher yields, decreased harvest times, etc.), not just what marketing claims."

Understanding dynamic vs. full spectrum

Many growers confuse dynamic spectrum with full spectrum lighting, but Henry says the distinction is critical.

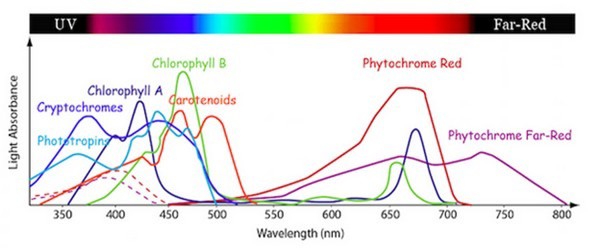

"Full spectrum usually means a single fixed output that can be used for both vegetative and flowering growth and conceptually contains all the color variations a plant may need through its lifecycle. Dynamic spectrum is a variable spectrum light that lets you adjust the spectral composition throughout the plant's growth cycle across a 24-hour period and/or across various substages of a plant's lifecycle."

This flexibility allows cultivators to optimize lighting per plant type or cultivar, dramatically improving yields, cannabinoid and terpene profiles, sugar content, antioxidant levels, and other metabolites.

"There's real science behind it. Spectrum shifts can be used for plant stress reduction during phase transition, crop steering by manipulating plant morphology like internodal stretching, leaf diameter, stomata size, just to name a few."

© Scynce LED

© Scynce LED

Features that actually matter

While "dynamic spectrum solutions" sounds high-tech, the complexity and degree of control vary widely between systems.

"Some fixtures only offer basic 'veg' and 'flower' modes, while others offer presets for cryptochrome/phytochrome activation to mimic sunrise or sunset. Others let you adjust 2, 4, even 6 channels of color — like red, blue, violet UV, far-red — or specific spectrum ranges like 2700K or 6500K, or even exact wavelengths like 660nm or 730nm."

A key consideration is power distribution. Fixtures that allow spectral changes without sacrificing total output provide the most value.

"With a 1000-watt fixture, ask: Are you dimming or switching off diode groups to change color, thus decreasing wattage? Can one channel access the full power of the fixture, or is it limited?"

If adjusting the spectrum reduces light intensity, yields can drop. Control methods also matter—manual, software-based, or integrated with environmental systems — and whether the system uses open standards like ModBus, BACNet, or custom APIs.

"Advanced platforms can automate spectrum shifts, but your team needs to understand how and why those changes matter. There's a difference between having the capability and using it to improve your bottom line."

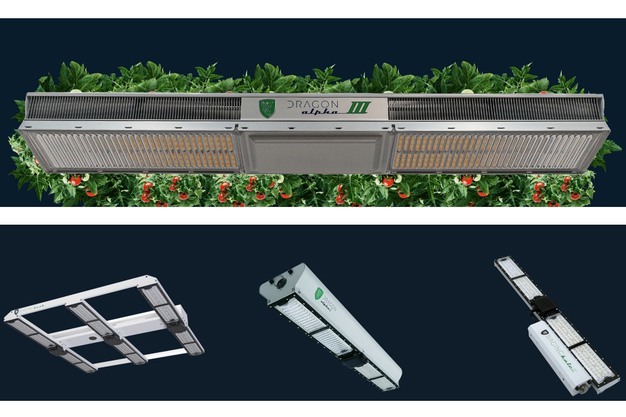

© Scynce LED

© Scynce LED

Complexity: a double-edged sword

Precision is powerful — but only if used effectively.

"I see growers buy advanced fixtures and complicated control systems only to revert to static modes because their teams aren't trained to understand spectrum or manage them," Henry says.

His advice: start simple.

"Use known responses, like cryptochrome/phytochrome cues — blue light in the morning, red/far-red in the evening — to mimic sunrise and sunset or control stretch. Then fine-tune based on your crops, genetics, and phenotypes. Let your team build from that baseline."

There's no universal formula. The right fixture is one your team can use to improve plant health, quality, and yield.

Automated DLI and integration with control systems

Henry emphasizes that light quality is just one part of the puzzle.

"The industry is shifting toward real-time DLI (Daily Light Integral) tracking. Systems like Argus' Axia can adjust LED output based on natural sunlight and consider utility rates to maintain optimal lighting while lowering energy costs."

These systems can also optimize the spectrum based on energy efficiency.

"Red and far-red photons take less energy to produce than blue or white. Automation can prioritize these wavelengths to reduce bills and boost growth. But seamless integration is key."

"Don't invest in a fixture without confirming it works with your HVAC, fertigation, or, in greenhouses, your blackout, shade, and curtain systems. You only see the full benefit when everything is aligned."

© Scynce LED

© Scynce LED

Environmental synchronization

Dynamic lighting is most effective when synced with environmental controls.

"Top growers align their light spectrum with temperature, humidity, and nutrient delivery," says Henry. "Top systems can automate that, but the value comes from interpreting the data and adjusting your protocols."

This holistic approach boosts quality and efficiency — if the team is trained to manage it.

ROI: balancing results and complexity

The financial upside is real — some growers report over 30% yield increases with lower energy use.

"But you only get that ROI if your team can manage the added complexity," Henry warns. "Start small. Build confidence before diving into complex strain- or cultivar-specific light recipes."

Jumping in too fast can lead to poor results and frustration.

"Scale as your team's skill grows. Dynamic spectrum is incredibly valuable for optimizing genetics, but may require pheno hunting. Success depends on well-defined SOPs and team readiness."

© Scynce LED

© Scynce LED

Questions to ask before you buy

To avoid costly mistakes, Henry advises asking the right questions:

Can you control individual spectrum channels, or are there just presets?

Does spectrum shifting reduce light output or intensity?

Will it integrate with your existing HVAC, fertigation, or blackout systems?

Then assess your team: Do they understand spectral tuning and automation? Can presets be customized? What support and training does the vendor offer?

Finally, consider internal limitations. Can your infrastructure and staffing support the system?

"Answer these honestly, and you'll save yourself a lot of time, money, and stress," he says.

Common misconceptions

Despite popularity, misconceptions persist.

Not all "dynamic spectrum" fixtures offer true multi-channel control. Full spectrum and dynamic spectrum are not the same. Compatibility doesn't guarantee full functionality. Dimming a diode group isn't spectrum tuning. And more features aren't better if your team can't manage them.

The future of light: flexibility is the investment

Henry sees dynamic spectrum as a way to future-proof cultivation.

"As a cultivator, you only have so many cardinal inputs — nutrients, environmental, and light. HID lights gave way to fixed-spectrum LEDs. Now you can fully control a third of your plant's input, and leverage that for real revenue gains."

"As more research reveals how plants respond to different wavelengths, growers with flexible lighting systems will adapt faster."

For more information:![]()

Scynce LED

Henry Berman, CCEO

[email protected]

[email protected]

scynceled.com