Tuta absoluta remains one of the most persistent and costly pests in tomato cultivation, both in commercial production and in seed multiplication. To face this challenge, the Syngenta team has successfully implemented the Biocaptur system, developed by the Almería-based company ATG Ingeniería, as an effective and complementary tool for pest control. As its use shows, however, Tuta absoluta is not the only lepidopteran sensitive to the attractive power of light.

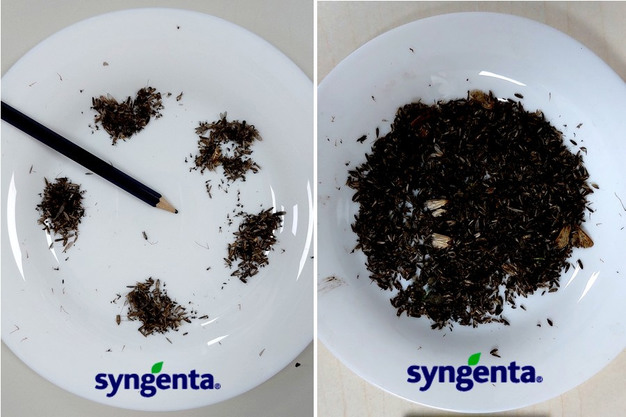

"We tested the device in 2022, a year when the Tuta absoluta infestation was particularly severe, and the results were really good. It didn't just capture Tuta, but also whiteflies, fungus gnats, and other insects. From that moment, we were convinced by all the advantages Biocaptur offered: it's a simple, durable physical method that helps reduce pest pressure without the need to increase chemical applications," explains Pablo Díaz, seed production research scientist at Syngenta.

A physical solution within integrated management

Syngenta's experience with Biocaptur began at its El Ejido center (Almería), where the first proof of concept was carried out. Later, the device was sent to the company's hybrid tomato seed production facilities in Kenya, where Syngenta has nine hectares dedicated to the multiplication of genetic material.

© Syngenta

© Syngenta

"In Kenya, we had a very serious problem with Tuta absoluta, especially during the hottest months. We sent the first Biocaptur units there, and the results were so good that we ended up buying one for each greenhouse. Today, we're working with 13 units in total, and they're part of our standard production protocol, including during crop changeover," Díaz details. "The device operates autonomously and activates at night, when insects are most active, and has proven to be an effective, clean, residue-free tool that continuously captures adult Tuta absoluta, breaking the reproductive cycle and reducing pest incidence."

Alongside integrated pest management, the use of Biocaptur also helps reduce reliance on chemical products, something particularly important in seed production, where plants must remain residue-free, Díaz highlights. "In seed multiplication, certain products can't be used because of the risk of affecting material quality. With this system, we can maintain plant health without compromising purity or productivity. And since it's a physical tool, its effectiveness doesn't degrade over time."

"The device works very well alongside scouting, preventive pruning, and localized applications, adding up to an integrated and sustainable approach. In fact, Syngenta is now developing several projects for organic hybrid seed production, where Biocaptur could play a key role," he adds.

© Syngenta

© Syngenta

A made-in-Almería tool integrated into Syngenta's global network

Developed and manufactured in Almería, the Biocaptur system has attracted the interest of international groups like Syngenta, showcasing the innovative potential of local solutions for global intensive agriculture.

"I really liked that it was a local company, with a product developed here that fits perfectly into Syngenta's global sustainability strategy. There's a lot of talent in Almería, and when given the right resources and visibility, great ideas emerge, and Biocaptur is a clear example of that," says Díaz.

Today, Syngenta uses Biocaptur units in Spain and Kenya, and its use is being evaluated in other producing countries such as India. The experience accumulated over three seasons confirms the strength of this tool within Syngenta's global approach. "With Biocaptur, we've found a way to complement existing pest control measures, reduce chemical use, improve the sustainability of our production, and maintain what defines our seeds: quality," Díaz concludes.

© SyngentaFor more information:

© SyngentaFor more information:

Syngenta

https://www.syngenta.es

© SyngentaBiocaptur

© SyngentaBiocaptur

Tel: +34 641 517 153

[email protected]

https://biocaptur.com/