The Dutch company Hortilife, which specializes in turnkey projects for greenhouses and irrigation systems, is consolidating its strategy in Mexico with an office and a warehouse in Querétaro since 2023. Its goal: to offer cutting-edge technology adapted to local needs, and contribute to more efficient and sustainable agriculture, says Genaro Balderas, the company's representative in Mexico.

The company, based in Deventer, the Netherlands, has industrial facilities specializing in the manufacture of irrigation units, disinfection systems, nanobubbles, and ultraviolet light equipment. "One of the great challenges of Mexican agriculture is having access to quality water. The country is very large and there are great variations in climate, soil, and water quality, so it is necessary to have the right system in place to manage irrigation water and avoid wasting this essential resource."

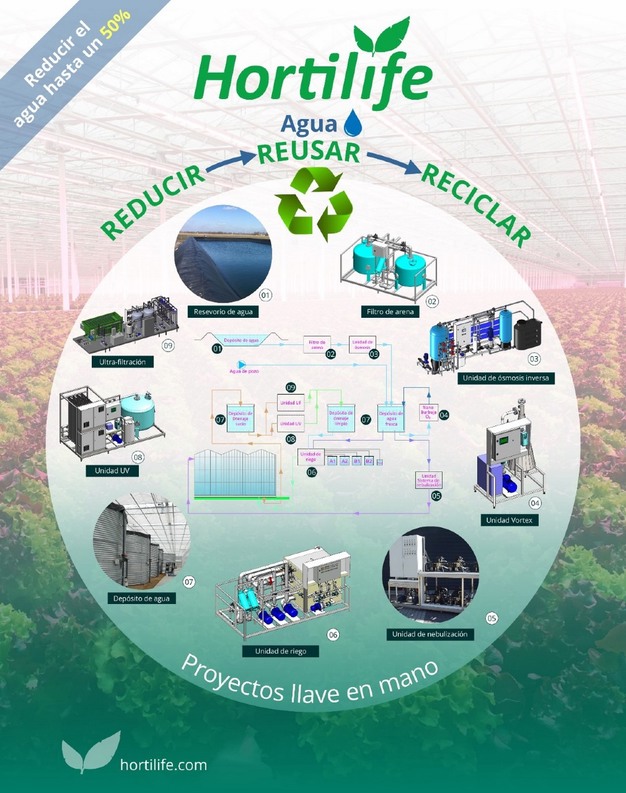

"Hortilife is working on the implementation of systems that allow up to 95% of drainage water to be reused, thanks to recirculation and disinfection processes that allow making the best use of drainage water and leached fertilizers."

© Hortilife

© Hortilife

Genaro Balderas, Hortilife's representative in Mexico

Save water and fertilizers

Today, the biggest part of the high and mid tech growers in Mexico do not recirculate their "expensive and rare" irrigation water, which they take from big sub soil wells. Growers now start to realize that it is very important to save on water and fertilizers, for several reasons. "Most growers drain out 40-50% of their irrigation water. Which is very costly. Investments on re-using the water and fertilizers are earned back in a few years. The huge volume of groundwater consumption is decreasing enormously, which has a major impact on the groundwater stock in Mexico."

The high percentage of drain water (50%) is caused by the high nutrients figures in the well water. So the first step is to make the well water suitable for irrigation and re-circulation, says Genaro. "Bad quality irrigation water cannot be used for re-circulation. The first step is Reversed Osmosis, to prepare make the perfect irrigation water which is suitable for re-use as well."

© Hortilife

© Hortilife

Ultra filtration unit

Disinfection

Drainage water cannot be used without it first undergoing a disinfection process to ensure that it is not a vector for diseases, nematodes, viruses, or other pathogens potentially present in the water. "To ensure 100% disinfection, we use several techniques, mainly ultrafiltration, ultraviolet light or Ozon."

"Ultraviolet disinfection is the most widely used method today; however, ultrafiltration systems are also increasingly implemented, as they guarantee 100% disinfection through dissolved air flotation (DAF), burned glass filters, and membrane filtration. In this way, up to 95% of drainage water can be recovered. And not just that; the salts from the fertilizers are also retained, which allows for them to be reused," says Genaro. "This is no small feat. We can easily recover 30% of the fertilizers present in drainage water, so the cost of the equipment pays off in 4 or 5 years thanks to the fertilizer savings it ensures."

"In addition, it should be noted that this system also offers significant savings in terms of both energy and wear and tear on water extraction equipment, especially given that with aquifers at increasingly lower levels, it is necessary to invest in more powerful pumps to reach and extract deep water with a higher presence of sediment."

The most important part for Ultra Filtration is the prefiltration, by dissolved air flotation (DAF) and burned glass filters. 'When the prefiltration is done in the right way, the ultra filtration works perfectly and hardly needs back flushes to clean We see several Ultra filtration system in the field with poor prefiltration, which means a lot of back flushing/ cleaning (= losses of water and fertilizers) and still a risk of viruses which can pass the Ultra filters because of this. This makes it so important for the growers to be informed very well about the technics they are buying."

© Hortilife B.V.

© Hortilife B.V.

Dissolved Air Flotation, crucial in addition to using ultra filtration.

Local stock to serve the market

It should be noted that since March 2024, Hortilife has had a warehouse and offices in Querétaro, allowing it to maintain a permanent stock of PVC and irrigation units. "This material is common in European projects, but scarce in Mexico, which is why we are committed to having a stock that guarantees a quick response to producers and immediate availability for repairs, expansions, or new projects. This is something that distributors and customers have thanked us for from the outset."

© Hortilife

© Hortilife

Exclusive distributors

Hortilife is the exclusive distributor in Mexico for Logitec Plus, a manufacturer of peat and coconut mixers that produce homogeneous and standardized substrates. "This offers a significant advantage, because agricultural producers can use coconut processed in Mexico—especially at a time like this, when the coco coir market is under pressure—and obtain a uniform mixture, which is essential for plant development," says Genaro.

The company also collaborates with Signify (Philips) on horticultural lighting solutions. "In Mexico, where solar radiation is high, but cloudy periods, and comparable short days, will affect the production, these lighting strategies are key to providing crops with the light they need, make the days longer, and are especially useful in seedbeds, grafted crops, or for the production of export vegetables such as tomatoes or lettuce."

"We cannot forget that the United States is our largest market, but also that it is very competitive; that is why agricultural companies are not so much looking to grow in terms of volume, but rather to lower production costs, and that is why investments are geared more toward technification than expansion."

"In fact, technification is the future of agriculture," says Genaro, "and innovation in irrigation, substrates, and lighting will determine the sector's competitiveness in the coming years."

© Hortilife B.V.

© Hortilife B.V.

For more information:

Hortilife

[email protected]

www.hortilife.com