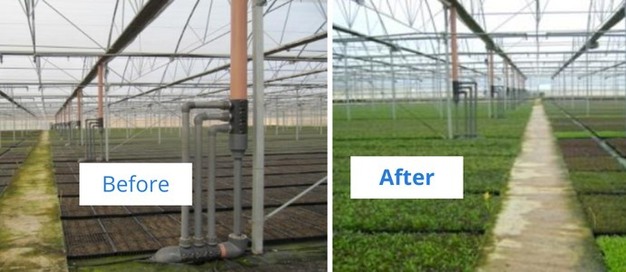

"Growers rarely consider water as an agent that accelerates the deterioration of their infrastructure. However, irrigation water can carry microorganisms, sediments, and organic compounds that form biofilms inside gutters, drip systems, filters, and pipes", the team with Hydroponic System says. "This biofilm causes blockages, reduces irrigation uniformity, and promotes biological corrosion processes that shorten the useful life of irrigation systems. Installing a water disinfection system for agricultural use is not only a sanitary measure but also an investment in the durability of channels and pipes."

© JH Hydroponic Systems S.L.

© JH Hydroponic Systems S.L.

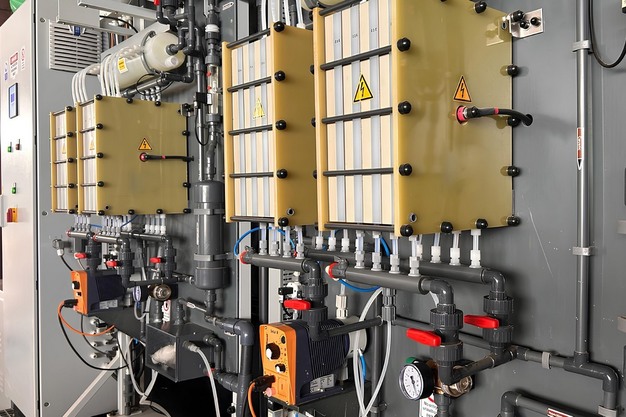

Pure hypochlorous acid (PHA) is a broad-spectrum disinfectant that can be generated at low operating cost. It is highly effective against biofilms and pathogens such as bacteria, fungi, and algae, which can cause plant diseases. PHA also improves root health, supports environmental disinfection in seedbeds, and does not corrode materials when applied with the appropriate parameters. Unlike aggressive chemicals, it does not degrade plastics and metals. In addition, PHA allows continuous and controlled generation, making it suitable for 24/7 treatment in recirculation systems. It is also compatible with organic crops.

Because of these characteristics, PHA-based systems are particularly suitable for protecting channels, pipes, and drip lines without weakening the materials. PHA prevents the formation and spread of biofilms, which trap particles and cause blockages in drippers and nozzles. By keeping internal surfaces clean, microbial fouling is minimised, reducing friction and localised corrosion. This helps maintain stable flow rates and irrigation uniformity, which is essential for avoiding water stress and inconsistencies in crop production.

© JH Hydroponic Systems S.L.

© JH Hydroponic Systems S.L.

The use of PHA also reduces the need for physical interventions such as mechanical cleaning, aggressive flushing, or premature replacement of pipes or channels. In arid climates, where pad-and-fan cooling systems are common, PHA extends the service life of wet parts, providing farmers with a practical solution that improves system durability and reduces maintenance costs.

When comparing PHA to other disinfection solutions, each method presents advantages and limitations depending on water quality and facility needs. Commercial chlorine and hypochlorite are effective but can generate chlorinated by-products toxic to crops and are corrosive to some plastics and seals. Ultraviolet (UV) treatment works well as a pre-treatment but does not remove biofilm attached to surfaces or function effectively in open circuits with sediments. If pipes are already contaminated downstream, UV-treated water becomes reinfected. UV also requires filtered, clarified water with good transmittance. Peroxides, while useful as oxidants, mainly provide oxygenation. At recommended doses, their oxidation power is limited, and at higher doses, they can detach biofilm layers that clog drippers, with biofilm reappearing within weeks.

In contrast, PHA is effective against biofilms, can be generated on-site, allows continuous monitoring, has a lower impact on materials when correctly dosed, and is compatible with beneficial microorganism treatments. For installations with recirculation, external networks, and exposed gutters, PHA provides a balanced solution between efficiency and infrastructure protection.

© JH Hydroponic Systems S.L.

© JH Hydroponic Systems S.L.

Where is it particularly advisable to install a PHA system?

The installation of a PHA system is particularly recommended in greenhouses that recirculate drainage, where the risk of pathogen and biofilm accumulation is high. It is also suitable for high-density crops such as strawberries, cherry tomatoes, or peppers, where uniform irrigation is critical for consistent yields. Farms with recurring dripper clogging or frequent pipe replacements also benefit from PHA, as it reduces the need for premature replacements of metal or plastic gutters.

A correctly sized PHA system minimises the need for mechanical cleaning and intensive chemical washing while enabling remote monitoring through automated installations tailored to each facility. This approach reduces labour costs, lowers the frequency of production downtime, and decreases the replacement rate of pipes and gutters. In many cases, commercial installations achieve payback within a few production cycles, although the precise dosage and system design must always be based on technical analysis of the water and irrigation network.

© JH Hydroponic Systems S.L.

© JH Hydroponic Systems S.L.

In conclusion, disinfecting irrigation water with PHA is not only a hygiene measure but also a strategy to protect agricultural infrastructure. By preventing biofilm formation and corrosion, gutter and pipe systems maintain their performance for longer, reducing maintenance costs and extending service life. For growers of high-value crops in open fields, greenhouses, and tunnels, a PHA system helps ensure consistent irrigation, improved plant health, and long-term profitability. Farms that experience blockages, corrosion, or premature replacement of irrigation systems may benefit from adopting this solution.

For more information:

Hydroponic Systems

www.hydroponicsystems.eu