At Proefcentrum Hoogstraten, a new foil greenhouse for strawberries has been installed. The AirVent concept was designed with a strong focus on the growing role of robotics in soft fruit production, the challenges of cultivating in warm and humid conditions, and the need for maximum labor efficiency.

© MJ Tech

© MJ Tech

© MJ Tech

© MJ Tech

Out of the ground

"In the Netherlands, strawberries are already widely grown out of the soil, but in other markets, open-field production is still common. Gutter-based cultivation is becoming increasingly popular, however. Growers want to protect their crops from rain, hail, or extreme drought, save water and nutrients, and reduce chemical inputs. On top of that, it's more labor-friendly, more efficient, gives higher yields, and results in better fruit quality," explains Robin Dirks of Growtec, one of the two companies behind the AirVent concept.

The greenhouse was developed jointly with Rovero, a specialist in foil structures. "Growers are looking for a total solution for soft fruit," says Robin. "Depending on their needs, we can supply a complete package: tunnels, gutters, irrigation, and substrate containers." He also notes that combining glasshouses with foil greenhouses is becoming more attractive. "Strawberry production is weather-dependent, and there are periods when returns are lower. A foil greenhouse is a more cost-effective option than glass, and the AirVent can even be installed without a permit."

© MJ Tech

© MJ Tech

© MJ Tech

© MJ Tech

Smart details

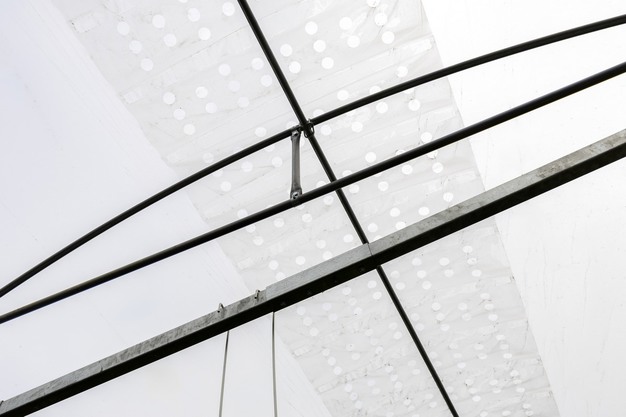

The AirVent includes several innovative design features. It comes with continuous roof ventilation—gutters of 110 cm running the full length of the structure—and uses a newly developed, patented film called VENTO. This film combines a perforated inner layer at the ridge with a solid outer layer. The system allows warm air and excess moisture to escape naturally once temperatures reach around 18°C, creating passive ventilation. "The greenhouse ventilates itself, and you can feel the difference the moment you step inside," says Robin.

The AirVent has a gutter height of 2.5 to 3.2 meters and is exceptionally wide at 4.4 meters, compared to alternatives of around 3.3 meters. This width directly supports further automation in soft fruit production, something becoming increasingly urgent with the shortage of skilled labor. "You want to work as efficiently as possible. With the wider structure, you can hang an extra gutter in every span, which means less work for spraying or for using UVC technology."

© MJ Tech

© MJ Tech

© MJ Tech

© MJ Tech

Demo greenhouse

Of course, no one will invest in a greenhouse based on a drawing—or even on an article like this. That's why an AirVent greenhouse has now been built at Proefcentrum Hoogstraten, well-known for its expertise in strawberry cultivation and for testing diverse growing methods. "The center attracts many visitors from the Netherlands, Belgium, and beyond. For us, it's the perfect location to showcase what the AirVent can do," Robin concludes.

© Growtec

© Growtec

Growtec will be present at the International Mechanization and Demonstration Strawberry fair on September 20 at Proefcentrum Hoogstraten.

For more information:

Robin Dirks

Growtec

[email protected]

www.growtec.com

Rovero

Rovero

Jacco van Delden

Tel.: +31 (0)162 574 574

[email protected]

www.rovero.com