As once stated by FAO, the domestication of plants was a very significant event in human history, and the need to protect these domesticated plants from abiotic and biotic stress factors subsequently led to another important agricultural breakthrough: protected cultivation.

Greenhouse production is an increasingly common reality around the world, and the last 20 years have brought a revolution when it comes to efficient and regionally adapted technologies, as well as in terms of acreage. A study by researchers at the University of Copenhagen who made use of detailed satellite imagery and AI revealed that greenhouse cultivation now covers at least 1.3 million hectares of the Earth's surface. This figure is almost three times higher than previous estimates.

This expansion has been greatest in the countries of the Southern Hemisphere, where significant growth is still expected from an increasing number of technology providers. In Chile, Azimut Invernaderos has positioned itself as an emerging player in the development of technological solutions for horticulture and other sectors such as floriculture and nurseries.

© Azimut Invernaderos

© Azimut Invernaderos

Based in the O'Higgins region, the company founded by the Cerón brothers aims to help growers become less vulnerable to climatic uncertainty by offering metal structures and climate automation systems adapted to the reality of Latin America.

"Our main objective has always been automating greenhouses and making growers more efficient through automation; to achieve greater control of climate, humidity, radiation and relative humidity, reduce the amount of labor for growers, and lower energy costs, all through a passive approach," says Cristian Cerón. "But above all, we develop technology that is accessible to everyone, from small growers to larger companies."

© Azimut Invernaderos

© Azimut Invernaderos

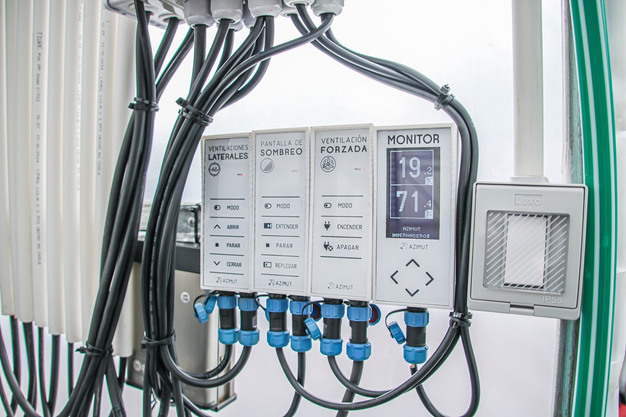

"Based on that, we started manufacturing and implementing metal greenhouses with high quality standards in terms of coverings or automation, and we also developed our modular climate controllers."

The controllers, designed and manufactured by Azimut's team in Chile, are installed in compact cabinets and allow the grower to scale their level of automation: from basic ventilation to shading screens, monitors and more complex systems. The metal structures of the greenhouses are manufactured locally in the company's workshop, while inputs such as netting, fittings or motor gearboxes are sold as a complement. "We manufacture curved and gothic greenhouses, and for extreme areas we add reinforcements, creating very compact and durable structures."

© Azimut Invernaderos

© Azimut Invernaderos

One of the biggest challenges, according to Cerón, is changing the culture in the agricultural sector: "Many growers still opt for wooden greenhouses with roofs with a two-year useful life, even though our metal structures, while requiring a higher initial investment, quickly pay off thanks to their durability and efficiency."

"There are subsidies, but access is limited and that is slowing down the transition to higher quality structures. For now, most of Azimut's projects are carried out for large companies, but we expect the culture of investing in technology to increasingly also reach medium and small producers.

Crop diversity and new opportunities

In the O'Higgins region and other areas of the country, greenhouses are expanding with hydroponic leafy vegetable crops, as well as tomatoes, chard, peppers and cucumbers. "Although full production during the off-season has not yet been achieved, with partial control of the environment, it is possible to extend the season, and with that allow producers to increase their profits," says Cristian.

© Azimut Invernaderos

© Azimut Invernaderos

"Other sectors, such as the cherry sector, are investing heavily in basic protection structures adapted to large areas. However, at Azimut we are keeping the focus on vegetables, flowers, nurseries and other specialized crops, where automation and climate control can make a difference in terms of efficiency and safety."

Looking to Latin America

Azimut's passive climate-controlled greenhouse models are based on three principles: covering material properties, structural design and automation. These principles remain at the core of the current strategy. The main goal is to achieve climate control with the minimum possible consumption of energy and natural resources, and with lower investments than those required for intensive climate control systems.

With projects already underway in different regions of Chile, Azimut is now targeting neighboring markets such as Argentina, Peru and Brazil; countries with higher agricultural development and great potential for affordable climate control technologies.

"We want the region's producers to have the right tools to face climate uncertainty and become less dependent on external resources. And we believe that our model can make a significant contribution," says Cerón.

© Azimut InvernaderosFor more information:

© Azimut InvernaderosFor more information:

Azimut Invernaderos

Tel.: +569 78888343

[email protected]

https://azimutinvernaderos.cl