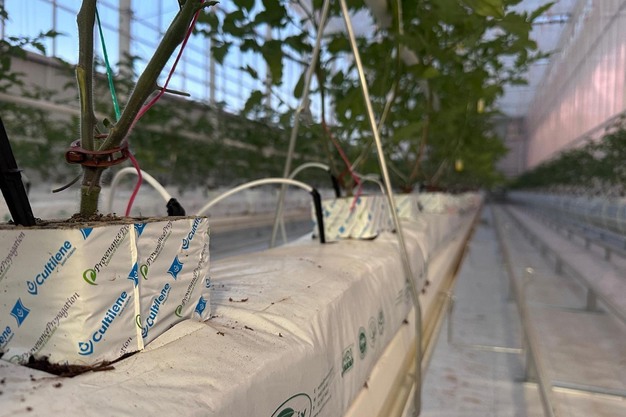

When Dr. Jack Mooney, CEO of Provenance Propagation, visited the Apex Greenhouses Demo House in Virginia, South Australia, the occasion marked more than just a friendly site tour. The latest collaboration between the two companies centers around the Demo House, designed not only to showcase the latest growing techniques but also to serve as a dynamic hub for grower education and research.

"This collaboration is enabling us to pioneer more efficient, innovative, and sustainable ways of growing food, while also helping us meet today's challenges and prepare for the future of agriculture," Jack shares.

© Provenance Propagation

© Provenance Propagation

A demo house built for growers, by growers

During a recent event, the Demo House hosted a full-day Plant Empowerment workshop, led by Ton Habraken of Svensson Climate Screens. The session focused on optimising plant health by carefully balancing light, water, energy, and assimilates, a holistic approach that continues to gain traction among progressive growers.

Attendees received hands-on training in key areas such as selecting the right climate screens, managing airflow, and enhancing light diffusion. They also explored how to interpret plant signals not just through hard data, but through careful observation which combines science with experience in the growing process.

"Growers walk away with tools they can apply directly in their operations."

© Provenance Propagation

© Provenance Propagation

A longstanding partnership, poised for growth

Jack shares that Apex has been their trusted glasshouse builder for years. "Our longstanding partnership with Apex has been built on a foundation of trust, shared innovation, and a mutual commitment to quality. As one of Apex's long-time customers, we've relied on their expertise as our trusted glasshouse builder for years."

He mentions that as they are looking ahead to their upcoming expansion, Provenance is excited to continue this collaboration, which plays a crucial role in realizing their vision for growth. "Apex's deep understanding of our needs and their dedication to excellence make them an essential partner in bringing our future glasshouse and greenhouse projects to life. Beyond infrastructure, this collaboration is helping us pioneer more efficient, innovative, and sustainable methods of food production."

© Provenance Propagation

© Provenance Propagation

Tackling the realities of transition: From workflow to integration

Transitioning propagation into a new facility comes with a unique set of challenges, particularly when it comes to workflow efficiency and systems integration. According to Jack, one of the key hurdles is adapting labor and operations to a space that hasn't yet "earned its rhythm." As he explains, "Even the best-designed facility will reveal its quirks only after you've started working in it. It's not until you're moving trays and tools that you find where the bottlenecks are."

Workflow issues often stem from inefficient layouts, such as long walking distances, awkward bench arrangements, or misaligned zones for potting and dispatch. These can severely impact productivity, especially when combined with staff still learning new systems. To address this, he emphasizes the importance of preparation and feedback. "We map our workflows before a single plant moves in. Then we run a few small production cycles to see what breaks down, and more importantly, why," he says. Visual cues like color coding, clear signage, and designated tool zones help reduce human error, while tracking key metrics like plants per person per hour allows the team to catch inefficiencies early.

Systems integration is another complex challenge. In a new build, irrigation, fertigation, lighting, and environmental controls often don't synchronize perfectly right away. "You think you've got everything calibrated, and then an irrigation cycle spikes the humidity and throws your VPD off," he shares. To tackle this, his team calibrates each system independently before conducting joint stress tests. Standard operating procedures (SOPs) are developed early to keep responses consistent, and an active issue log allows staff to flag anomalies in real time.

Ultimately, the success of the transition depends on being proactive, listening to feedback, and treating the new facility as a system that needs tuning. "A new space will test your assumptions. But if you're listening closely to your systems and your people, you'll find your stride."

© Provenance Propagation

© Provenance Propagation

What's next: Scaling smart, building resilience

As the demand for high-quality young plants continues to rise in and around Australia, Provenance Propagation is planning even further expansion with custom-built, climate-resilient glasshouses engineered to meet specific site and crop needs.

"We're not just building more greenhouses, we're building better ones. Facilities that can withstand challenging environments while optimizing plant health, labor, and energy efficiency."

For more information:

Apex Greenhouses![]()

[email protected]

apexgreenhouses.com

Provenance Propagation![]()

Jack Mooney, CEO

[email protected]

www.provenancecorp.com