As energy costs climb, labour shortages tighten operations, and input supplies grow less predictable, like with the recent global substrate shortage, the horticulture industry is in a period of reflection and adaptation. Katia Zacharaki, plant scientist at Niab and Director of InnoPhyte, who has extensive experience in vertical farming, hydroponics, and strawberry cultivation, shares about both challenges and opportunities in the industry.

"I realised early on that there was a lack of people who could bridge plant science with business. Startups need people who can wear many hats," she says. "And in horticulture, especially in the UK, we don't have enough degrees focused specifically on hydroponics or advanced plant science. That gap made me valuable."

Today, through her consulting company and collaborations with research organizations, she also plays a key role in UKUAT, a membership organisation dedicated to uniting vertical farms, greenhouse growers, technology providers, and enthusiasts to strengthen the urban agriculture sector.

© InnoPhyte

© InnoPhyte

Katia Zacharaki (InnoPhyte) and Mark Else (Niab)

Reducing nitrogen without sacrificing yield

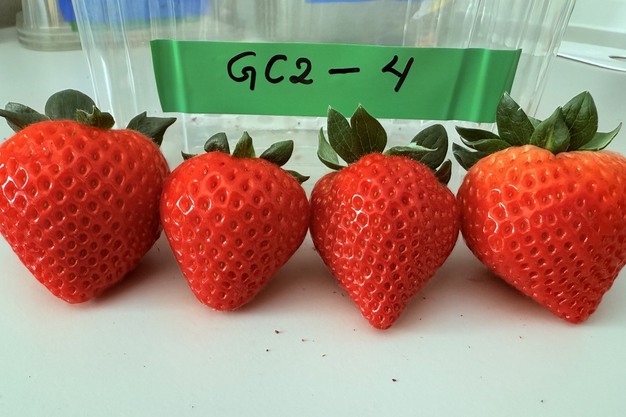

One of Katia's current projects, InnoPhyte Consulting in partnership with Niab and Flex Farming, focuses on optimising nitrogen use in Total Controlled Environment Agriculture (TCEA) strawberry systems, specifically with the high-yielding Malling Ace cultivar.

"We're developing a nitrogen demand model to reduce fertiliser input with minimal sacrifice of yield," she explains. "What's exciting is that we're also testing CO₂ supplementation to counterbalance any potential yield drop and improve fruit quality."

Beyond fertiliser efficiency, this approach brings several operational advantages. By reducing nitrogen, the plants produce smaller leaves, which helps to control canopy size. This, in turn, reduces the need for manual de-leafing and can lower labour costs. A smaller canopy also means less humidity in the growing environment, making it easier and more cost-effective to manage environmental conditions, particularly important when trying to minimise energy use.

The trial, which began in early 2025, is already showing promising early results. "We're seeing outstanding performance so far, and the plants are producing well with noticeably improved quality and higher yields under enriched CO₂."

© InnoPhyte

© InnoPhyte

The Malling Ace variety

Substrate shortage: Crisis or opportunity?

The global shortage of coconut coir substrate has growers re-evaluating their production methods.

"Most strawberry growers use coir, but it's imported from tropical regions. It's inconsistent in quality, and can carry pathogens," Katia mentions. "This shortage might actually be an opportunity to rethink our dependence on it."

She sees potential in substrate alternatives and hybrid systems. "Techniques like NFT (nutrient film technique) are being reconsidered, although strawberries are vulnerable to root diseases, so it's not a simple transition."

Some innovations are bridging the gap. "Companies like NGS in Spain are using systems that mix substrate and NFT to reduce reliance on coir while keeping disease risk manageable. It's a clever solution."

© InnoPhyte

© InnoPhyte

One of the projects featuring Ahman Mohseni (Flex Farming), Katia Zacharaki (InnoPhyte), Mark Else (Niab) and Jim Stevens (IPC)

Financial pressures across farming models

Whether it's polytunnels, glasshouses, or vertical farms, growers across the board are experiencing similar financial strains.

"The pressures are real and relentless," she explains. "Labour costs, minimum wage increases, pension contributions, national insurance (especially in the UK) all build up. Add energy costs on top, and it becomes difficult to stay profitable, especially for smaller facilities."

One significant challenge comes from the pricing power of supermarkets. "Margins are incredibly tight," she notes. "In many cases, we see small growers going out of business because they can't sustain operations under these conditions."

As a result, innovation and cost efficiency have become a necessity. "Every year, growers have to find ways to cut costs while maintaining quality."

The overpromises and unknowns of vertical farming

"Many companies overestimate what they can achieve in terms of yields and underestimate the scientific unknowns," Katia says. "Especially with strawberries, there's still a lot we don't know when it comes to growing in TCEA. These gaps in knowledge can sink a company if not addressed properly."

She warns against what economists call the "sunk asset trap." "Companies invest heavily in infrastructure and systems. Even when it becomes clear the model isn't working, they keep pouring money in because they're already so committed."

She argues that deep research should not fall solely on the shoulders of private startups. "It should be publicly funded so that findings can be shared and the entire sector can grow more sustainably. Right now, startups are doing the heavy lifting of R&D, which diverts resources from where they're most needed: building a viable business."

© InnoPhyte

© InnoPhyte

Niab TCEA strawberry propagation

Tackling the energy crisis with smart strategies

The global energy crisis has forced growers to rethink their operations.

"In the UK, accessing renewable energy is the most sustainable long-term approach. But we know that's not immediately possible for everyone."

In the meantime, she suggests that growers explore a combination of creative strategies to manage energy costs more effectively. One approach is to adjust lighting systems, including methods to manipulate light in ways that significantly reduce energy consumption without compromising crop performance. Another promising avenue involves negotiating directly with energy providers. Some operations in the UK, for example, have secured access to cheaper off-peak rates or flexible supply arrangements that can make a meaningful difference in their bottom line.

Finally, she highlights the importance of optimising environmental controls. By managing humidity and temperature more precisely, growers can achieve additional energy savings while maintaining optimal growing conditions. She believes that as the energy grid becomes greener, high-tech CEA will become significantly more viable.

Collaboration is key

Katia emphasises that the way forward must be collaborative, not siloed.

"At UKUAT, we're trying to bring everyone together. Growers, tech companies, researchers should all work together. Only by working across disciplines and sharing knowledge can we overcome the industry's major hurdles. We need to stop reinventing the wheel in isolation. With public support, open research, and smarter business models, the future of CEA can be both sustainable and profitable."

For more information:

For more information:

Innophyte Consulting

Katia Zacharaki, Founder and Head Researcher

[email protected]

https://innophyte.co.uk