That the pepper sector is rapidly evolving in substrate choice is no surprise to anyone in the horticulture industry. Still, new insights keep emerging, including at Klasmann-Deilmann, where the focus is on fine-tuning crop steering.

For the upcoming season, the substrate producer expects strong demand for its coco-based Growbags while it conducts trials with its organic substrate slabs made from wood fiber and coco. Until the end of August, a trial is running at Dutch trail center Botany, where the organic Growbag is being tested alongside rockwool. A slab containing TerraCoal® biochar is also included in the trial.

© Klasmann-DeilmannWorking with moisture sensors in pepper cultivation is worthwhile for gaining good insights into the substrate mat.

© Klasmann-DeilmannWorking with moisture sensors in pepper cultivation is worthwhile for gaining good insights into the substrate mat.

Quick generative start

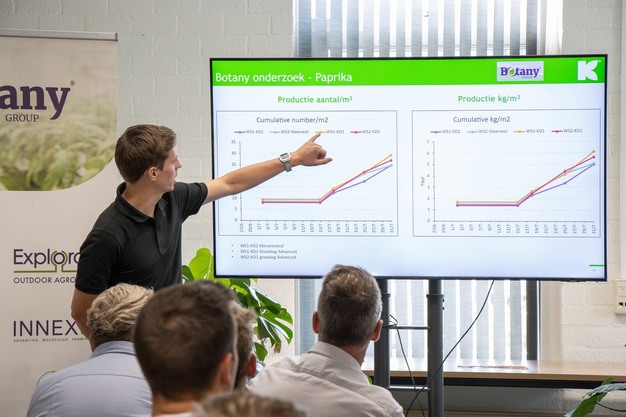

On August 6, Klasmann-Deilmann organized an afternoon event on resilient cultivation for local growers, where the Botany trial results were discussed.

The trial period was relatively short. Green peppers were planted on May 15, an unusual time of year for peppers. "But with the current changes in the pepper market, we need to gain experience as quickly as possible," explains Jan Vanoverschelde, Group Product Manager Growbags at Klasmann-Deilmann.

At Botany, Klasmann-Deilmann's Growbags are being tested alongside rockwool. "In terms of yield, our substrate matches rockwool, and in fact we see slightly higher production," Jan says. "Our Growbag pushes the crop into the generative phase earlier, so the first fruits arrive right on schedule."

This result was also confirmed in another trial at Proefcentrum Hoogstraten in Belgium, part of a four-year Zero Waste project finishing this year. "There, peppers were planted in December 2024. In spring, plants grown on our Growbags started producing one to two weeks earlier than those on rockwool," Jan adds.

© Klasmann-DeilmannJan Vanoverschelde during the meeting on resilient cultivation on August 6

© Klasmann-DeilmannJan Vanoverschelde during the meeting on resilient cultivation on August 6

Frequent dripping with less volume

Once peppers are in production, it's important for the crop to keep developing vegetatively. Growers can influence this with the right crop steering.

Klasmann-Deilmann's research shows that growers who have years of experience with rockwool need to adjust their strategy a little when switching to an organic substrate. "On our Growbag, which is based on wood fiber and coco, we see that growers need to irrigate slightly more frequently, with a somewhat lower drip volume," explains Jan. "Maintaining fruit weight is also an important point of attention."

In the Botany trial, two different irrigation strategies are being tested, Jan shares. "One follows our own recipe, and the other applies rockwool steering while using our Growbag. In both approaches, the Growbag performs very well."

Also involved in the research is Kytos, a company specialized in rapid scanning of the crop's microbiome. The microbiome is known to play a role in crop resilience, but there is still much to discover. "We're conducting fast scans of the microbiome and its variation," says Jan. "We look at irrigation water, drain water, and the substrate, and analyze how these factors influence the microbiome."

© Klasmann-Deilmann

© Klasmann-Deilmann

A glimpse inside the greenhouse on August 6 at Botany

Biochar

What stands out most in the trial is that the Growbag with TerraCoal biochar is easy to re-wet. "At certain moments this results in a bit more drain, because the slab reaches moisture level faster. That takes some getting used to for growers, but it can also be an advantage," explains Jan. "Our Growbag is naturally very generative, and adding biochar to the mix supports vegetative growth. On top of that, biochar has a positive effect on the microbial life in the substrate, which is something we'll continue to study further."

Another big plus of using TerraCoal in the Growbag is that it creates a climate-neutral product. According to Klasmann-Deilmann, the biochar compensates for the CO₂ emissions of the entire production process, including the slab itself, the plastic film, and transport.

Jan acknowledges that sustainability may not be the very first thing on growers' minds, but he does see that it is becoming increasingly important, alongside other advantages such as the compostability of all Growbags. "In the long run, we want to set up our own recycling system for Growbags."

© Klasmann-Deilmann

© Klasmann-Deilmann

In tomato and cucumber cultivation a lot of experience has been gained in recent years. Here, the most commonly used mix is 80% Greenfibre wood fiber and 20% coco. Pepper cultivation has its own specific questions.

Growbag with coco substrate

When Klasmann-Deilmann first introduced its Growbag, the strongest interest came from cucumber and tomato growers. Now, the pepper sector is clearly moving as well. One grower is already producing peppers on a large scale using the slabs.

Jan notes that growers of green peppers especially appreciate the Growbag for its quick generative push. "That's exactly what they want. Other growers, however, prefer a substrate with more buffering capacity. For them, we can adjust the recipe accordingly."

For growers considering a different substrate but not yet ready to fully switch to an organic one, Klasmann-Deilmann also offers coco-based Growbags. These are already widely used in commercial practice. "Growers are often a bit more familiar with working on coco substrate, so they are more comfortable making that step."

That's why the ongoing trials with the organic Growbag are so valuable. "We're building up experience together with growers," Jan emphasizes.

© Klasmann-DeilmannJesse Clemens of Klasmann-Deilmann during the meeting on resilient cultivation

© Klasmann-DeilmannJesse Clemens of Klasmann-Deilmann during the meeting on resilient cultivation

For more information:

Jan Vanoverschelde

Jesse Clemens

Klasmann-Deilmann Benelux

[email protected]

www.klasmann-deilmann.com/nl/