Measuring irrigation accurately in pepper cultivation has always been a bit of a challenge. Spotting general trends is usually possible, but getting precise data on how much water the crop actually receives? That's where things get tricky.

Now that more pepper growers are switching to organic substrates in response to crop loss issues, the question of how to measure irrigation effectively has come back into focus.

A tomato grower who grows on coconut coir using weighing systems from Wireless Value recently brought the sensor manufacturer together with substrate producer Van der Knaap, in the Netherlands. This collaboration led to the development of a fully integrated weighing system tailored specifically for pepper cultivation.

The new system is designed to filter out disturbances in the raw irrigation data, such as plant movement and harvesting activity. This results in much clearer and more accurate insights, giving growers the tools they need to better manage their irrigation strategies.

© Thijmen Tiersma | HortiDaily.comContrary to what one might expect from an irrigation data measurement system, most of the technology is found at the top of the greenhouse.

© Thijmen Tiersma | HortiDaily.comContrary to what one might expect from an irrigation data measurement system, most of the technology is found at the top of the greenhouse.

Substrates in transition

At Aan de Vogelaer in Honselersdijk, substrate producer Van der Knaap runs its own innovation center, known as de Kas. Here, they compare their own substrates with popular alternatives on the market. As more growers transition to organic substrates, Van der Knaap aims to provide them with accurate data on how crops perform on specific substrates—especially their own coconut-based products. But to do that, solid data is essential. And when it came to peppers, there simply wasn't a good measurement system in place.

"Organic substrates behave differently than rockwool, so the way you measure things has to be different too," explains Willem Kögeler, R&D specialist at Van der Knaap. "Even the way you insert a moisture sensor into the slab can affect the accuracy of the readings."

Up until now, their test greenhouse relied on a combination of standard weighing scales and moisture sensors. "We just had to live with the fluctuations in the data," Willem adds. "There was no better solution for pepper crops, until now."

Specific properties of pepper cultivation

The new weighing system is designed to filter out all the external factors that usually cause fluctuations in irrigation data, explains Kees van Vliet from Wireless Value. These factors include things like the natural expansion and contraction of the greenhouse structure, tension or slack in the crop, and a unique trait of pepper plants: unlike cucumbers and tomatoes, peppers aren't suspended by support wires throughout the entire crop cycle.

"That's a big difference," says Kees, account manager for Agri at Wireless Value. "The weight of a pepper plant on the support wire isn't consistent. When the plant is under stress, it tends to droop, which directly affects the measurement."

In crops like tomatoes or cucumbers, the plants are more consistently supported, which makes weighing data more stable. But in pepper cultivation, these small shifts can seriously skew the numbers, unless you have a system that knows how to correct for them.

© Thijmen Tiersma | HortiDaily.com

© Thijmen Tiersma | HortiDaily.com

On the left, Willem Kögeler (Van der Knaap) and Kees van Vliet (Wireless Value) at the gutter where the new weighing system gathers irrigation data.

Smart calculations with weighing data

At GreenTech Amsterdam, Wireless Value gave visitors a sneak preview of the new weighing system, which is currently being tested as a prototype in the greenhouse at Honselersdijk. The system is mounted on a frame that hangs independently from the greenhouse structure. Two load cells are positioned above the frame, and two are placed below.

"The top load cells measure the total weight of the entire system, while the bottom ones only measure the crop and the substrate," explains Kees. "We compare the data from both sets to filter out any interference."

Developing this system involved more than just hardware. It required close collaboration with Willem and the Van der Knaap team, plus some serious number-crunching—something Wireless Value's tech experts are well equipped to handle.

As a specialist in wireless measurement technology for horticulture, Wireless Value also built a smart data portal to work alongside the sensors. This platform turns raw measurements into clear, practical tables and graphs, giving growers real-time insights they can actually use to fine-tune their irrigation strategy.

The pepper weighing system is designed to measure not just one, but multiple substrate slabs at once. "We offer the option to weigh two, and up to five slabs simultaneously," says Kees. "This gives a much more reliable picture than measuring a single slab in one location with a sensor."

© Thijmen Tiersma | HortiDaily.comIn pepper cultivation, there are quickly double the number of wires compared to tomato and cucumber. The Wireless Value weighing system can be applied in all V- or 4R-systems. The construction includes a bypass rod substituting the crop wire, with plants attached to the bypass rod instead of the crop wire.

© Thijmen Tiersma | HortiDaily.comIn pepper cultivation, there are quickly double the number of wires compared to tomato and cucumber. The Wireless Value weighing system can be applied in all V- or 4R-systems. The construction includes a bypass rod substituting the crop wire, with plants attached to the bypass rod instead of the crop wire.

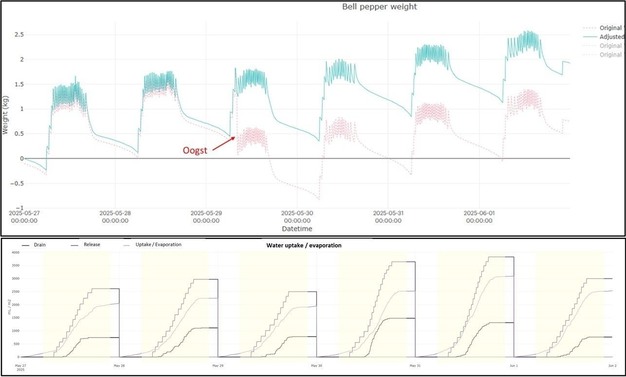

Clear watering line

Here's a fun little detail from the pepper cultivation at Van der Knaap. Thanks to their new weighing system, the team at Wireless Value can remotely tell exactly when peppers are being harvested in Honselersdijk. Kees explains, "The algorithm recognizes the harvest." Willem laughs and adds, "We don't tell them when we're harvesting, but they can still see it!"

This ability to filter out harvesting events is the first step toward using data to guide irrigation strategies, says Kees. "Our goal is to help growers set up an optimal irrigation line."

The next development focuses on taking plant growth into account. The teams at Van der Knaap and Wireless Value are currently working on that. "By cleverly combining the data from the load cells, we'll soon be able to show the plant's weight gain per square meter, per hour, and per day. This extra layer of information opens up new possibilities for growers, giving them more insight and better control over their crop."

Right now, data on drainage, irrigation, and weight gain are still displayed together in one graph. But that's expected to change as the system continues to evolve. As Kees puts it, "The most important thing for now is delivering clear data to growers so they can optimize their irrigation strategies."

© Wireless ValueThe red line indicates the raw data, logically dropping post-harvest. With algorithm use, a corrected green line is achieved, which does not react to the harvest making the chart more readable and thus useful for monitoring irrigation and crop evaporation. Growers, among other things, can see when the crop reaches saturation. Click here to enlarge the chart.

© Wireless ValueThe red line indicates the raw data, logically dropping post-harvest. With algorithm use, a corrected green line is achieved, which does not react to the harvest making the chart more readable and thus useful for monitoring irrigation and crop evaporation. Growers, among other things, can see when the crop reaches saturation. Click here to enlarge the chart.

Irrigation based on data

For Van der Knaap, which recently entered into a strategic partnership with Premier Tech, the data from the new weighing system plays a key role in comparing different substrates. As Willem explains, "We want to gain insight into the moisture percentage in the slab, and how much moisture is lost overnight. Each substrate and slab type has its own capacity for holding water. Regardless of the type, a grower might want to lose, say, ten percent of moisture during the night. With accurate data, we can advise growers on how to achieve that target moisture loss using their specific substrate."

Reliable data is an essential part of Van der Knaap's communication with growers. As a specialist in organic substrates, the company markets its vegetable-growing substrates under the Forteco brand.

According to Kees, there's been a lot of interest in the system developed by Van der Knaap and Wireless Value. "Almost everyone I talk to says, 'Let me take a look at that!' This system now makes it possible in pepper cultivation, too, to really see how the greenhouse climate is affecting the plant, for example, the impact of high or low relative humidity, or how climate screens influence growth."

Wireless Value's technology is compatible with nearly all climate computer systems. This integration makes it possible to control irrigation directly based on data from the climate computer. "That takes a load off the grower's shoulders," Kees says.

Now that the pilot setup has proven successful, Wireless Value is moving forward with scaling up the system for broader production. The goal is to make the system available for other crops as well, such as aubergine, which, like peppers, has both hanging and standing growth parts.

© Thijmen Tiersma | HortiDaily.com

© Thijmen Tiersma | HortiDaily.com

By using a slightly larger gutter section than the standard gutter for testing, the gutter overlaps the standard ones and is almost level with the remaining gutters. Important, as this way the plant does not notice it is on a scale.

For more information:

Kees van Vliet

Wireless Value

Mob.: +31 6 411 537 27

Tel.: +31 591 633200

[email protected]

www.wirelessvalue.nl

Willem Kögeler

Van der Knaap Groep

[email protected]

www.vanderknaap.info