Efficient fruit packing has become increasingly crucial for producers striving to balance product quality, labour constraints, and profitability. Addressing these needs, Milbor PMC offers two tailored solutions: the manual weighing line and the dynamic weighing line. Both systems have their own advantages, says Piotr Milewski, CEO of Milbor PMC.

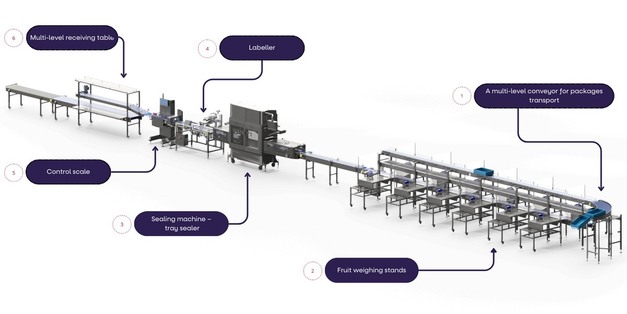

According to Milewski, the manual weighing line is ideal for products requiring careful sorting, such as strawberries or raspberries. "This system relies on human operators, who manually verify the weight of each punnet using precise scales placed at weighing stations. When a package is overweight or underweight, the operator adjusts its weight manually before it moves to the next processing stage. The primary advantage of this system lies in its efficiency combined with accuracy. Manual weighing line minimises product waste and supports ergonomic working conditions, thereby enhancing employee engagement and reducing costly overfilling mistakes. The line can be customised and adapted to any packing facility."

© Milbor sp. z o.o

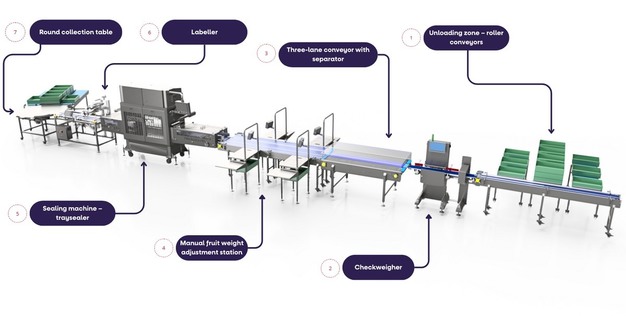

© Milbor sp. z o.o

For operations where products require minimal sorting, weight control only, or repacking, the dynamic weighing line offers a semi-automatic alternative, Milewski explains. "This system uses a checkweigher and a 3-lane conveyor with a diverter that automatically directs packages based on their weight. Only underweight or overweight packages are routed for manual adjustment. Once the weight is correct, the punnets go to the next stage. Thanks to its compact design, the dynamic line is an interesting choice for pack houses with limited space. It significantly reduces operator workload, as employees focus solely on adding or removing fruit, rather than conducting full weight checks."

© Milbor sp. z o.o

© Milbor sp. z o.o

Milewski states that despite their differences, both systems deliver notable improvements in productivity, about 30%: "The system also reduces operational expenses by decreasing labour requirements and minimising losses from overweight products. Furthermore, they share a modular design, allowing for future adjustments and scalability, as well as feature increased durability thanks to high-quality manufacturing."

"With these solutions, fruit producers can measurably reduce overweight losses and increase work efficiency while keeping gentle handling of delicate products. Selecting between the manual and dynamic weighing line depends on the product, sorting requirements, and operational goals. To explore more about both solutions, find out if they fit your business model and calculate ROI, please contact the Milbor PMC advisor," Milewski concludes.

For more information:

Maciej Chmielewski

Milbor PMC

Tel: +48 538 359 172

Email: [email protected]

www.milborpmc.com