“Before I used Gardin, I mainly focused on the climate conditions in the greenhouse. I tried to set this as optimally as possible for the plants. With Gardin, I can measure the effect of those climate conditions based on the plants themselves. This allows me to control the greenhouse climate more specifically and measure the effect of the changes much faster," says Leonard Boer, co-founder of FromBoer, a Dutch family-owned business currently led by brothers Arjan and Leonard.

The Boer brothers realized that a significant hurdle to enhancing their farm's potential was the lack of direct feedback from the plants after changes to their climate strategy, which delayed their ability to fine-tune each lettuce variety effectively. Eager to maintain their pioneering status in lettuce cultivation and bridge this gap, they turned to Gardin and its groundbreaking plant photosynthesis sensor.

Ever since 1968, FromBoer has flourished through continuous innovation. Their 4ha facility in Dinteloord, the Netherlands is widely appreciated in the industry as a benchmark for innovation and sustainable practices.

Leonard and Arjan Boer

Plant-driven growing

FromBoer grows seven different lettuce varieties directly from seed and supplies fresh produce to supermarkets across Europe. However, this diversity presents a unique challenge for Leonard as each lettuce variety has specific needs regarding temperature, light, humidity, and nutrients. Balancing these requirements to optimize productivity for all varieties throughout the year is a complex task, even for growers like FromBoer with extensive horticultural knowledge, demanding a nuanced understanding of each plant's preferences.

Since the summer of 2023, FromBoer and Gardin have embarked on a journey to implement the practices of plant-driven growing, driving greenhouse management decisions based on direct measurements of plant physiology. "Using Gardin’s sensor, I have been able to get real-time feedback on how our lettuce plants are responding to the environment. This advancement has enabled us to transition from relying on intuition to making decisions based on quantified plant photosynthesis activity."

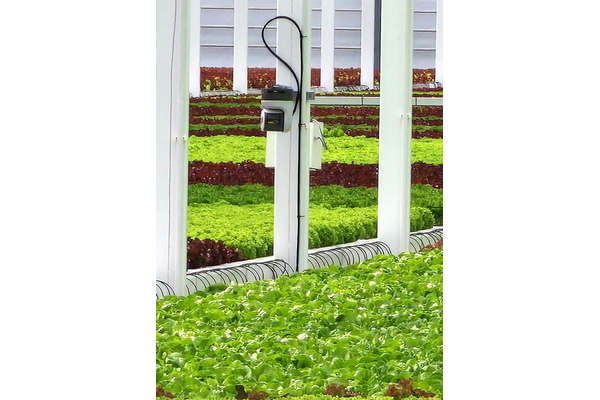

The Gardin sensor installed at FromBoer's facility

Respond to changes

Plant-driven growing enables growers to quickly respond to changes in the growing environment and assess the effectiveness of their decisions. FromBoer’s collaboration with Gardin has led to improvements in vital areas such as VPD (Vapor Pressure Deficit) control, lighting efficiency, and irrigation strategies. This data-driven approach to plant optimization helps growers refine their practices over time, leading to progressively better outcomes in terms of both yield and resource efficiency.

The story of FromBoer and Gardin unveils an exciting step change for the future of agriculture. It presents a future where growers can directly interact with and respond to their crops, continuously refining their cultivation strategies based on plant feedback. FromBoer is not just using pioneering technology; in collaboration with Gardin, they are setting a precedent for the future of food production, showcasing the immense potential of plant-driven growing in modern agriculture.

For more information:

Gardin

Damiana Price, Head of Marketing

[email protected]

www.gardin.co.uk

FromBoer

FromBoer

+3118 070 0266

[email protected]

www.fromboer.nl