For some people, dinner is a tasteless, albeit practical, affair. Older people and those with dysphagia, who battle to swallow, often have blended foods. This aids in swallowing but doesn't taste or look appetizing. 'It doesn't have to be that way,' thought Peter Nieuwkerk, owner of the Budelpack Group in the Netherlands. That's why he founded Gastronology.

This company develops 3D food recipes and appealing 3D food designs. It does so together with master chef Eugène Swalen. Swalen is from the SVH, a Dutch hospitality educational institute. After two years of development, the first recipes are ready. The plan is to produce industrial-scale 3D food by 2022. That will be done under license, starting in Europe.

Peter Nieuwkerk and Eugène Swalen.

How does it work?

"We focus on fresh vegetables. We have recipes with, for example, cauliflower, broccoli, carrots, and fennel. We steam and mash these vegetables. Then we add ingredients to make the recipe suitable for 3D food printing. However, each recipe contains at least 95% fresh, natural vegetables," Peter explains.

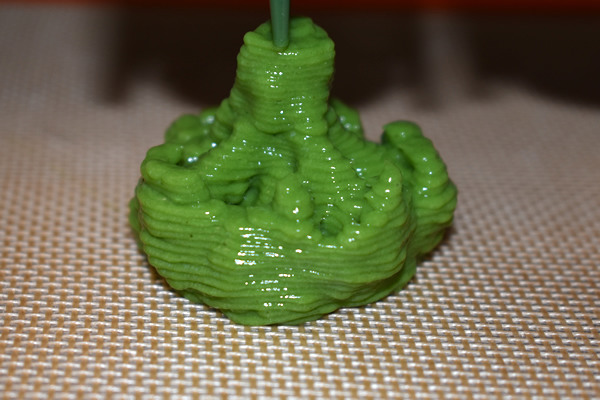

"One kg means one kg of vegetables. The emulsion is cooled, and then we can print." In 3D food printing, the cartridge is filled with fresh food puree. The nozzles then move quickly over a silicon print surface. The semi-finished product is layered in a controlled manner into a 3D product.

Refining what's good

"We focus on three target groups too. These are dysphagia and oncology patients, and children who eat too-few vegetables. We give food a new dimension for them. Taste, form, gastronomy, and technology come together in unique 3D food products. This is a breakthrough in some people's mealtime experience," Peter says.

"These are those with chewing, swallowing, taste, or appetite problems. Their dining pleasure and quality of life improve. That's because 3D food is easy to eat, tastes better, looks more inviting, and increases the appetite. Our slogan is 'refining what's good,' for good reason."

"Think of cancer patients that can't taste certain flavors anymore. Thanks to personalized nutrition, we can accentuate certain flavors. Then these people can again experience how vegetables really taste. We can, naturally, combine other care aspects with this. Taking medicines - especially in large quantities - can be off-putting. With 3D food printing, medicines can be added into the food. In this way, even swallowing pills becomes less unpleasant."

A 2,000kg/day goal

"We combine creating fresh, refined 3D food recipes with fun 3D product shape designs. This makes eating vegetables a treat too. That's for, for example, children who currently fall far short of the recommended consumption. We can, say, print vegetables in the shape of a frog or lizard," continues Peter. Gastronology will be working hard to increase production. "We're now working on a kitchen scale. But we want to move to an industrial scale. Our goal is to eventually print 2,000 kg a day. So we need good vegetable suppliers."

Gastronology itself won't make the 3D food products. It's going to focus on design and recipes. It's also going to supply the purees to licensees. They will then print on an industrial scale. Budelfood is one of these licensees. It's part of the Budelpack packaging company, which Peter owns. But he's looking for other global licensees too. "That's one of the reasons I got into this," says Nieuwkerk.

"The Budelpack Group packages for third parties. We're, therefore, dependent on our customers as to what we can pack. Budelfood can actively enter the market to offer 3D food. We have the building, the people, separate production areas, and certifications available. That's an advantage."

Plastic 3D printing is already well-advanced. But, 3D food technology is still in its infancy all over the world. "We're the furthest along with this worldwide now," Peter says. Gastronology works with Dutch parties. These include TNO, Wageningen UR, and HAS University of Applied Sciences. It's, however, open to further collaboration.

"Innovation requires cooperation because we can't change things alone. So, it's nice that we're located where we are, at Delta Agrifood Business (Dablab), [in the Netherlands]. This is an open innovation and expertise center for business and education," concludes Peter.

For more information:

For more information:

Peter Nieuwkerk

Gastronology

Unit 122, 24 Van Konijnenburgweg

4611 HL, Bergen op Zoom, NL

Tel: +31 (0) 164 745 799

Email: p.nieuwkerk@gastronology.com

Website: www.gastronology.com