In the greenhouse of the Turkish propagator Altin Fide, humidity could be a big issue - either an excess or a lack of it would both harm the youngplants being propagated at the company. A greenhouse air handling unit (GAHU) turned out to be the solution. The installation is designed to eliminate fungi, bacteria and viruses while controlling the greenhouse environment. "We're steering on the Vapore Pressure Deficit, which gives a better representation of how the plants are doing."

Emrullah Gumus with Altin Fide shows how the youngplants now are flourishing. "Humidity was an issue in or greenhouse - either an excess or a lack of it. We turned to Timfog to ask how technology can help us," he says.

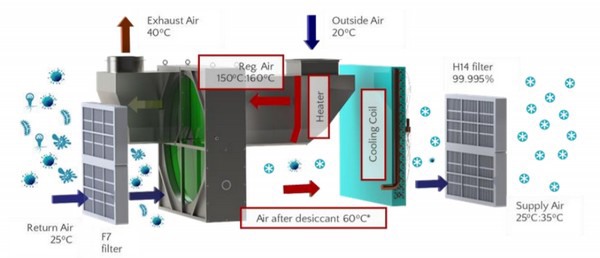

Listening to the growers problems, the Turkish company Timfog developed the GAHU. The unit consists of a desiccant rotor and a burner, with the most recent design in the industry. The system is predicated on the principle of taking and heating the air with the help of the solid zeolite dehumidifier rotor. In here, the zeolite dehumidification rotor is heated to 150 degrees Celsius by the regeneration air so that the humid air is dried and resent to the relevant site, eliminating fungi, bacteria and viruses in the process.

According to Emrullah, the effect of the machine is great and the humidity is way better controllable now. "There's no more condensation on the plants, nor on the paths in the greenhouse. We've finished the season with high quality plants, just like we want to do."

One of the biggest benefits is that the humidity can be adjusted while the greenhouse is cooled. GAHU, with it's cooling ability, makes it possible to control the temperature while de-humidifying. "Especially in summer having a high temperature will result in other complications." He explains how before, they were steering with the relative humidity, yet nowadays they work with the VPD. "That's important since the relative humidity does not represent the plants condition, but the VPD does."

The VPD (Vapor Pressure Deficit) is used by growers to assess how dry the air is at a given moment. VPD is a key metric for maintaining optimal plant biomass and yield, and the right VPD is central to preventing mold and disease, avoiding poor nutrient uptake. Because VPD is independent of temperature, it provides greater insights than relative humidity does.

Thanks to the installation it is possible to keep the greenhouse closed and according to Emrullah that's a big benefit, also when looking towards the future. "With the insect pressure rising, closing down greenhouses will be important. This tool will help us getting there."

For more information:

For more information: