Ventilation is the process of air exchange, removing inside air from inside the plant production facility and replacing it with outside air. Ventilation is also important for maintaining CO2 levels and removing excess moisture when there are no active systems installed to manage those factors. Ventilation is commonly used as the first stage of cooling in greenhouses. It can also be used for vertical farms to limit energy used by compressors when the outdoor conditions are favorable.

The total volume of air that moves through the greenhouse (or indoor facility) in one hour is referred to as the Air Change Rate per Hour (ACH). The ACH required depends on several factors, including outdoor climate and the use of heating/cooling systems. In general, ventilation rates should be optimized to balance carbon dioxide enrichment during heating, to remove excess moisture when the it's cold outside, and to eliminate excess heat during cooling. Crop layout and row orientation will affect the direction and uniformity of airflow.

Natural (passive) Ventilation (NV)

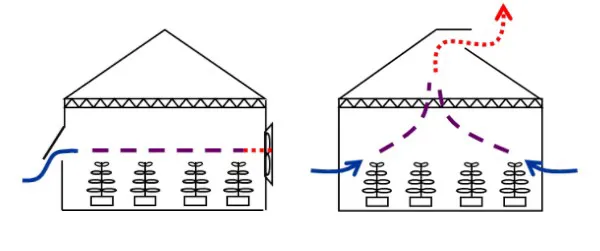

Natural ventilation relies on the forces of nature to drive airflow into and out of the greenhouse, either through buoyancy or with the assistance of wind. Typically, vents are located along the sidewalls of the greenhouse and in the roof. The vent location and size, as well as the use of insect screens and greenhouse orientation, will all impact the effectiveness of natural ventilation. Vents may be controlled manually or electronically using a computer control system. Natural ventilation has very low operational costs. Buoyancy-driven ventilation relies on air temperature differences in the air to move heat up and out of the greenhouse. It is most effective when the air temperature inside the greenhouse is greater than the temperature outside the greenhouse. Wind-driven ventilation relies on external forces to push outside air into the greenhouse, forcing the hotter inside air to circulate out. It is most effective when greenhouse vents are oriented to take advantage of prevailing winds.

Mechanical (forced) Ventilation (MV)

Mechanical ventilation uses fans to actively drive air into and out of the greenhouse. The greatest advantage to MV is the ability to control air exchange rates. Most commonly fans are located at one end of the greenhouse and vents are located at the opposite end, allowing for air to flow in one direction from opening to fan. The number and size of fans depends on the greenhouse size, location, crop layout, and use of evaporative cooling. Using fans with a variable speed drive will allow better control over the climate conditions and reduce energy use and costs.

For more information:

Doctor Greenhouse

www.doctorgreenhouse.com