On their own, the United Nations Sustainable Development Goals (SDGs) might not be very concrete. However, the goals are being taken into account in many annual reports. Even in the horticultural sector, companies know how to handle it, and the goals are applied in practice, for instance in breeding and the construction of greenhouses.

In last year’s brochure ‘Top Sector Horticulture & Starting materials and SDG’s: practice examples’, a few progressive projects were mentioned. These projects are meant to contribute to achieving the 17 goals before the 2030 deadline in the Netherlands.

Breeding

Take for example the development of drought and salt tolerant vegetable varieties or varieties that are resistant to downy mildew (Rijk Zwaan) or educating growers abroad on how to make the best use of ‘Dutch quality seeds’ (East-West Seed).

Greenhouse construction

Cultivation in greenhouses is another concrete concept. Certhon talks about it in the brochure. More with less is the motto here. The more advanced a greenhouse is, the better the cultivation can be controlled, says Lotte van Rijn. “Greenhouse cultivation already provides four times higher production and thirteen times less water usage compared to cultivation on open fields. Inside of a semi-closed SuprimAir greenhouse, the production is fifteen times higher, and eighty times less water is used.”

The difference between input and output is even more favorable in the various indoor farming systems. “The trick is to find the optimal growing solution for each area. We can’t do this alone. The entire horticultural sector participates. For instance, we work together with seed supplier Rijk Zwaan, and climate system supplier Priva. Our greenhouses and installations are part of the larger Dutch supply chain that brings food all over the world.”

Data

Dutch people are used to high-tech greenhouse systems, but this is not the case in other countries. “Interpreting graphics and adjusting settings, that is our horticulture”, says Freerk Visser of Hoogendoorn Growth Management, which is actively spreading the Plant Empowerment ‘gospel’ with its partners.

"However, when you place a high-tech greenhouse like that in China, it doesn’t automatically mean you double the harvest. Knowledge is also needed. We provide training worldwide – much through e-learning. For example, about the plant and greenhouse climate, energy optimization, and water management, and of course, how to control these elements in our greenhouse systems.”

Fairtrade

Exporting abroad is an option, but so is growing locally, which is what Agro Care is doing in Tunisia, although the produce is still finding its way back to Europe. “I hope that we eventually are also able to sell tomatoes in Tunisia”, says Kees van Veen.

He is aware of the drawbacks of growing in the desert but found a solution for both the water and transport challenges. “We transport the tomatoes without packaging, allowing 20,000 kilos to fit in the truck. If the tomatoes are packaged, it would only be about 10,000 kilos. As for water use: our greenhouses are state of the art and are in no way inferior to the ones we have back in the Dutch Westland. The water use is kept to a minimum. A kilo snack tomatoes need about 6 to 10 liters of water. Traditional cultivation in North Africa would use about ten times that amount.”

The tomatoes are grown Fair Trade. Unfortunately, not all of them are sold that way because supermarkets don’t ask for it, or the consumer doesn’t want to pay for it, says Kees. “I hope this changes in the future so that we can improve our contribution to the local development and are able to grow a part of the tomatoes for the local market.”

A selection of stories

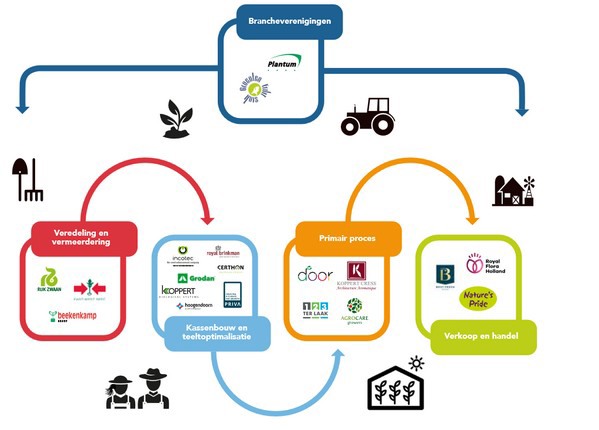

And then there is water (Priva), substrate (Grodan) and energy (Jacques Wolberts of the DOOR cooperative talks about it, just like Rob Baan of Koppert Cress and Edith Bentvelsen of Ter Laak Orchids). At the same time, trade, among others, in the capacity of Best Fresh Group and Nature’s Pride can also share their stories about food waste.

All stories about these concrete applications can be read here (in Dutch). Beekenkamp Group, Incotec, Royal Brinkman, Koppert Biological Systems, and Royal FloraHolland also get to tell their stories.