Crop protection products and packaging are two quite unpopular terms, especially among consumers. They are however terms that have to do with Liquidseal, an ultra-thin liquid packaging from the Dutch company of the same name which aims to extend the shelf life of perishable products in order to counter product loss. Co-founder Victor Monster: “Without packaging, many products don’t even make it to the supermarkets. Liquidseal can be seen as an extra cog in the machine of the supply chain that ensures the high-quality deliverance of perishable products to the consumers.”

Crop protection products and packaging are two quite unpopular terms, especially among consumers. They are however terms that have to do with Liquidseal, an ultra-thin liquid packaging from the Dutch company of the same name which aims to extend the shelf life of perishable products in order to counter product loss. Co-founder Victor Monster: “Without packaging, many products don’t even make it to the supermarkets. Liquidseal can be seen as an extra cog in the machine of the supply chain that ensures the high-quality deliverance of perishable products to the consumers.”

In 2005 they took their first steps and a recipe was developed with which lily bulbs attain a longer shelf life. After that, they succeeded with other ornamental crops like cut roses, carnations, and gerberas. In 2016 they stepped into the fresh produce sector. Liquidseal is already applied to avocados, citrus, mangoes, and papayas.

Before we go on, how does the product actually work?

“What we do is extend the shelf life of perishable products. Most products need oxygen to survive. If you completely seal off a product like that, which most of the time happens when using regular plastic packaging, the product will slowly waste away. We also seal off a product to air for the most part, but we let controlled and reduced oxygen in. What happens when applying an ultra-thin layer, is that you are left with a breathable packaging that controls the supply of oxygen and evaporation of water. It is also possible to add crop protection products to the Liquidseal and gradually release them to prevent things like mold from forming. Because of this, not as many crop protecting products are needed, but also there's less loss during and after transport.”

What was the reason behind the development of Liquidseal? To counteract food wastage or to counteract plastic packaging?

“The actual reason was to simply extend the shelf life. I am still amazed by the amount of costly produced food that gets thrown away because it is spoiled. Globally, we are talking about forty percent of the produced food that is not being eaten. In 2005, the issue of food waste and the packaging discussion was in a lull, but in the past couple of years, they seem to have peaked again. We try to make a positive contribution to decreasing of plastic and expect that, for some cases, we can replace the current plastic packaging, however, this will not be the case for all plastic packaging.”

After the introduction in the floriculture sector, it still took a while before the first steps were taken towards the fresh produce sector. Why did that take so long?

“After the introduction in the floriculture sector, we quickly started working on a recipe that had to work on hard-peeled tropical fruits. Those fruits have to travel from far, so long shelf life is necessary. You only have to deal with European and American laws and regulations. Our product is in line with the rules regarding Food Contact Materials, which means all of the components found in Liquidseal are on the list and are regarded as safe to the consumer. Only if you would eat five hundred mangoes in a single day it could cause harm. But eating that many mangoes in one day isn’t the best idea anyway if you ask me.”

How did consumers respond to the introduction into the fresh produce sector?

“The term packaging is often seen as negative by the consumer, crop protection products has the same problem. Add to this the fact that Liquidseal was still little known to unknown by the consumer, and that people often don’t trust what they don’t know. That is why we had an external bureau do a lot of consumer research for us. In the research, the consumers got informed about the product's properties and were given a closer look at the development process. Consumers need to know that without packaging, many (tropical) fruits don’t even make it to the supermarket. Certain steps must be taken if the consumer wants to be able to eat flavorful tropical fruits of high quality. Firstly you will meet resistance against the invisible layer, but as soon as people realize it’s biodegradable, compostable and has major organic certifications (Kiwa Covenant and CAAE Certification among others), they are on your side and become fans of the product.”

Before the product reaches the consumer it first goes through the growers, transporters, traders, and retailers. What does the use of Liquidseal mean to them?

“The growers are the first ones that handle our product, without any major investments, they can apply the Liquidseal to their harvest after having sprayed the product with the equipment they already have in place or by just submerging it. The real added value of our product, however, only becomes apparent until the logistics process. Traders and retailers get a higher quality product with an improved shelf life. Because of this, there is less product loss, it’s possible to opt for cheaper and more environmentally friendly transportation over the seas and the product can remain unsold for longer without going bad.”

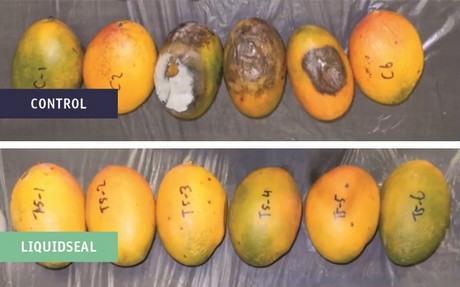

Mango Keitt of Colombian descent not treated with Liquidseal (above) and treated with Liquidseal (below) after 25 days of being kept at room temperature.

Is it also possible to harvest the product later than normal?

“Yes it is, it makes it possible to harvest the product when it is riper and when it arrives here it can finish ripening. After all, a mango is much more tasteful in the tropical areas it comes from than the same fruit we get here. Harvesting later improves the taste and sugar levels of the fruits.”

All of these are advantages, but are there also challenges?

“Our challenge is to convince all the parties involved in the supply chain that the money growers ask for products treated with Liquidseal is worth the investment. When a customer gets a container shipment of citrus and a lot of the product has gone bad, the costs to sift through that container to find the citrus that is still good is ten times higher than it would have been to treat the fruits with Liquidseal before shipping.

We have nothing to complain about in regards to the attention we get from the fresh produce sector, but we remain vigilant. We want to take things step-by-step and give the same advice to the users of our product. Having growers harvest at a later date is, for instance, a possibility, but when it comes to an introduction to the market it is not our intention to suggest any changes in the current way of harvesting only in regards to the application of Liquidseal.

In the meantime, small new companies keep on popping up in the sector, who all come up with ‘interesting’ new inventions. So it is only logical that companies want to test the product first. This goes for our product as well. People first want to see whether it works or not, for instance by monitoring treated and untreated avocados for the duration of one month to see when spoilage will occur.

When people are finally convinced we can start supplying them with the product. Production capacity is definitely not one of our limitations. The limiting factor is the personal guidance we want to give, since the product needs to be used in the right way. For instance, even when Liquidseal is used, it remains important to handle transport with care and to keep it cooled.”

In how many countries is Liquidseal being used already?

“Currently we are selling Liquidseal in twenty countries and every month we add more countries to our roster, most recently Turkey and South Africa were added. It is a continuous process in which we have to keep on dealing with different laws and regulations for each country. When we obtained the approval for the application on fresh produce with hard-peels, it was time to pop the champagne bottles in our office. However, afterwards, we were surprised by the laws and regulations that differ from country to country, even within Europe.” Laughing: “But if you look at it differently, this is also more often than not the reason to party and drink champagne. All kidding aside, because of all the different laws and regulations we do have a full-time Compliance Officer on our payroll whose job is to arrange and monitor the registrations.”

Has the ultimate recipe already been invented and what would the next goal be?

“The ultimate recipe is never finished, because there is always room for improvements. Our R&D department is currently working hard on developing edible packaging. This will make Liquidseal also applicable to for instance soft fruits or greenhouse vegetables. Think of strawberries, bell peppers and different types of berries. It is our goal to have this edible packaging ready to go to market in 2020. This packaging as well will, of course, fulfill all of the laws and regulations, because of this it is just a matter of waiting for registration and approval after the introduction. A simple formality, but nonetheless a formality that takes a considerable amount of time.”

This article previously appeared in the 3rd edition, 33rd volume of the trade journal, AFG Primeur. See www.agfprimeur.nl.

For more information:

Liquidseal

www.liquidseal.nl

info@liquidseal.nl