This is the challenge for which CleanLight has developed an answer that is easy to implement.: By the nursery or by the shipper. For an example see the video below:

In the video you can see how roses are being moved at high speeds past a set of CleanLight modules. Those modules emit a form of UV light that kills young mycelium, and does not harm the plant in any way shape or form. Treating flowers in this fashion has proven to extend the time before gray mould manifests itself on the flower. This means the flower stays clean for a longer period of time.

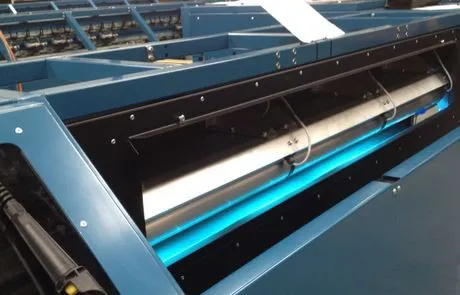

This post-harvest system may be incorporated into bunching machinery. That means the flowers are treated effectively, at highs speeds, from all angles. Alternatively, it is possible to do the work by hand. However, as with application of chemical fungicides it is important to apply the right dosage and it is important to treat the flowers from all angles for optimum result.

Generally speaking the investment in these systems amounts to about € 5,000 (US $ 6.500) for a system that may be incorporated into a bunching machine. For application by hand a CleanLight Pro module would suffice at a cost of approximately € 500 (US $ 650). Available from UFO Supplies and from Horticoop.

More information is available from Mr. Arjo Vandersluis at CleanLight in The Netherlands : +31-317-497620. arjo@cleanlight.nl .