Israeli firm, Amitec, designs information systems for industrial, security and renewable energy systems and have recently ventured into the horticultural market with their AgroAmitec 2D Climate Control System; a multi-lingual platform that is compatible with third party software.

“We signed a contract with the Volcani Centre; they brought their climate control know-how into our company and we put it in our command control platform and the result is AgroAmitec, which brings the next generation solutions to the horticulture market,” says Yehuda Segev, Amitec’s CEO.

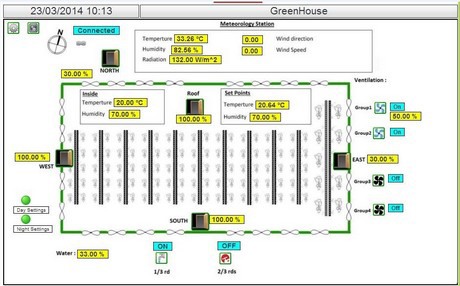

A similar concept to Priva or Hoogendoorn automation, 2D Climate Control monitors and manages a number of variables within the greenhouse environment ranging from (among other things): ventilation, chilling, fogging and heating, to screen control and CO2 management.

“This is a new approach to controlling the (greenhouse) environment in an agricultural building: day, night, winter and summer” said Segev.

“We can operate Israeli technology like the DryGair and the Agam units, or any other heating and de-humidifying system,” he said. And the platform - which can generate alerts and reports - can be monitored and controlled in real time, via the internet, or smart phones.

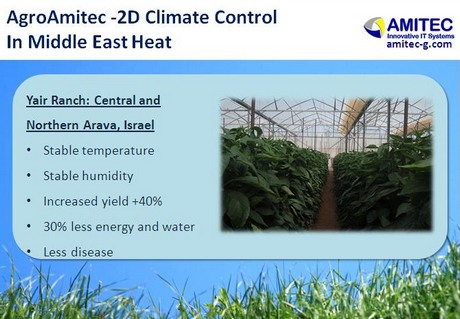

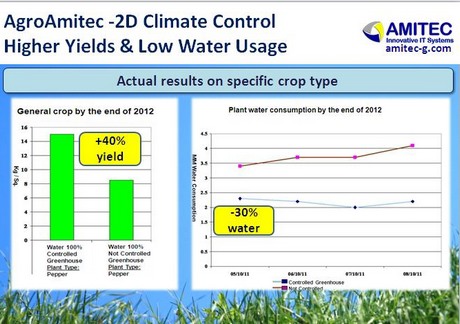

An Amitec study conducted at the Yair Ranch in Central and Northern Arava, Israel, showed the 2D Control System was able to stabilize temperature and humidity, reduce the occurrence of disease, and resulted in 30% savings on energy and water, with an increase of 40% in crop production.

“We expect great success for the system due to the global need to produce food more efficiently and economically in an environment where the costs of energy and other inputs are constantly increasing,” Segev said.

For more information

Amitec LTD.

Yehuda Segev

Tel: +972-39613729

[email protected]

www.amitec-g.com