CleanGrow was started in 2009/10 by Roy O'Mahony and Ciaran Long, both from Cork, Ireland. Roy's background is in Molecular Biology, he worked in Cambridge and the Max Planck institute in Germany working on Calcium ions and stress signalling in plants. "I left academia and did various jobs ending up helping to set up a plant tissue culture and vertical farming startup in Cornwall. A piece of technology we really wanted was a way to measure the composition of the fertilizer mix in-house. I searched for something affordable and suitable and I could not find anything."

Roy left that company and set up CleanGrow with Ciaran, who is a family friend from Cork, Ireland who had a successful career in the San Francisco financial industry with companies like CNET and CBS. They were funded by friends and family and Enterprise Ireland.

Real-time measurement

"Our initial research into possible methods for measuring multiple ions led us to the relatively unknown idea of solid state sensors. We had advice from scientists in Switzerland ETH, Professor Dermot Diamond from DCU Dublin and Professor Lisa Hall in Cambridge, plus the inventor of carbon nanotube sensing from Germany and started developing our product. I also made contact with Chris Blok from Wageningen based in Bleiswijk who gave me a great insight into the need for real-time ion measurement in horticulture.

"We simultaneously worked on developing a multi-channel potentiometer meter for measuring 6 ions at once, developing the miniature CNT sensors and working out the best calibration solutions to calibrate all 6 sensors at once for hydroponics and soil samples. The first model came out in 2011 and we were very well received at Hortifair winning a top 10 place in the new technology competition and also at the Analytica show in Munich also winning the most innovative new product award. The media attention at Hortifair led us to forming a friendship with Theo Gieling of Wageningen and Mr Jan Prins and Dick Zwartzfeld of Priva who had a deep interest in ion measurement in horticulture."

They then decided to move away from the traditional meter approach and put all the electronics into the probe to make a bluetooth probe containing 6 sensors that works with a partner app on iOS/Android so the user can utilize all the communications, GPS and power of smart devices. In 2017 CleanGrow won first place in the Royal Society of Chemistry Emerging technologies award.

"We got involved because I had done a lot of work promoting CleanGrow in the horticulture industry in the Netherlands since 2010", Roy says. They made friends with Mr Jan Prins, Dick Zwartveld, Theo Gieling and Chris Blok of Wageningen and people in Horticoop. It was suggested that measuring ions on top of all the other measurements in the timescale unit would be a good idea, and Leo Marcelis contacted Roy to ask if he would like to be part of the grant proposal.

"Time Scale kicked off in 2015 and our task was to fully automate ion measurement and make it remote access, so users on the ground could operate the device and access the data. This is what we have made. I have been obsessed with working out how to make a phosphate sensor and we solved it in 2016 and that is now part of the system; the unit can now measure 8 ions, ca, cl, k, na, nh4, no3, mg and P."

Nanotubes

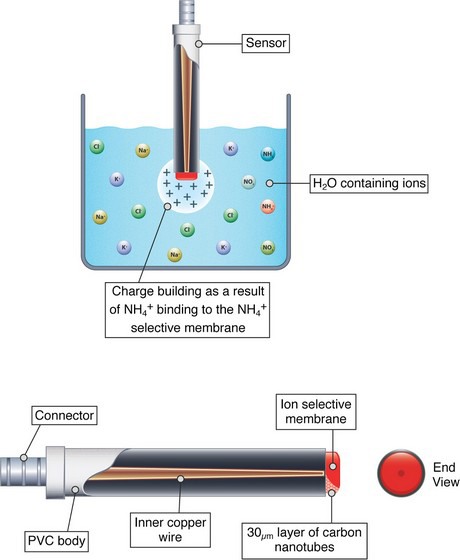

The CleanGrow technology uses carbon nanotubes as a transducing layer in the sensor. Roy explains how this works and what the advantage of this is. "Ion Selective electrodes work by attracting the ions of interest to the tip of the sensor, each sensor is coated with a specific PVC membrane containing a cocktail of detection molecules. Ions have a positive or negative charge and this creates a charge build up on the tip. This charge needs to be converted and amplified as an electron charge so it can move up the copper wires to the electronics, this is what the layer of Carbon nanotubes are doing, they are two thousand times more conductive than copper and work as a transducer. The charge of the ion is measured in relation to the fixed charge of a reference electrode and the electronics work out the potential difference as millivolts. Through a calibration process against known standards, the charge in an unknown sample can be converted to a realistic number as mmol or ppm."

CleanGrow is still in its early days, but there are already some labs in the UK testing it, a fertilizer company in Jordan, LETI research in Grenoble, NIBIO in Norway, and of course the timescale itself in Norway is in early days of testing in the main breadboard unit assessing the entire system in space-like conditions (minus the lack of gravity). "So far the feedback has been really positive", Roy says.

For more information:

CleanGrow

CleanGrowinfo@cleangrow.com

www.cleangrow.com