INA PLastics started in 2010 with the design for the new tray. "We wanted to make a more productive, efficient and environmentally friendly substitute to the bulky styrofoam trays", explained Kostas Tsonakis of INA Plastics. " The idea was simple: all we needed was to give to the insert tray, which was already being used in the EPS tray, the necessary rigidity to stand on its own without increasing its weight and the cost that comes with it."

The two trays: the insert tray gives the upper cell tray a lot of strenght.

Tsonakis explained that they made the insert tray slightly heavier than a standard propagation tray. To make the tray more rigid, a special 'negative' tray with a “space frame” structure was created. "The combination of the two trays ensured that it was light and rigid enough and ideal for on rail propagation. The resulted in many advantages like better plant growth, root development, cost efficiency and logistics."

As with everything new, Tsonakis said that in the beginning it proved to be very difficult to convince growers why they should use the new tray as an alternative to the Styrofoam trays. "It required a lot of strategic planning and teamwork to find the right growers and convince them. We knew we had created something innovative, but never expected its potential and wide range of application possibilities thanks to special features."

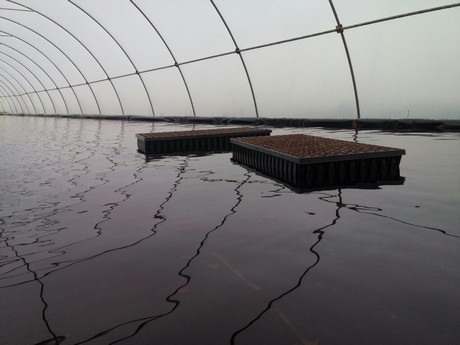

The floating trays.

One of those features of the Double Tray System was its ability to float on water. "Thanks to detailed engineering and design of the base and different material composition; the DTS is able to float on water carrying the weight of developed plants on any cell configuration."

Due to its floating ability, the DTS was immediately adopted by the tobacco growers, who gradually started replacing their EPS trays. "They started with the 210 cell initially and later on a 300 cell tray was found ideal. Tobacco growers saw a tremendous increase in plant quality and growth."

vegetables growin in the trays in an aquaponic situation

Besides the early adaptation of the tobacco industry, the company informs that also hydroponic and aquaponic growers have started with the use of the DTS for the cultivation of vegetable seedlings. "Currently the tray is commercially used in more than 20 countries worldwide and everyday a new grower starts with a trial. Many of them are so convinced when they see the results, that they do not want to go back to EPS trays."

The same trays on a rack situation.

As a result of the great adaptation, INA Plastics has decided to extend the range of the DTS. "We will add more configurations in order to support more types of crops and cultivations. We have recently introduced two new DTS trays in the 67 x 33 size; one with 171 cells, which is a perfect fit for melon and water melon propagation, as well as a 300 cell tray for pepper and industrial tomato crops. "

Kostas and Jacob Tsonakis at the Fruit Logistica in Berlin this year.

For more information:

INA Plastics

Kostas Tsonakis

[email protected]

www.dts-tray.com