Semi-closed technique also usable in conventional greenhouses

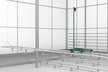

Double air hoses

In 2012, RedStar built the first semi-closed greenhouse in the Netherlands. Geurt Reinders of Enerdes developed the semi-closed system in conjunction with Canadian tomato grower Casey Houweling. The greenhouse features the characteristic air handling units and double air hoses.

Techniques from semi-closed greenhouse

When building the second phase last year, it was decided not to deploy a semi-closed greenhouse, but to use techniques from it to improve the conventional greenhouse. For instance, ventilators were placed under the gutter in order to properly control fogging. Enerdes was engaged to develop this, Frank says. "The ventilation system needs to be sustainable, use little energy and make little noise, be competitive in terms of price and also placed as closely to the gutter as possible." And they succeeded: "We developed a recirculation ventilation system that produces up to 50% more air volume, delivers double the working pressure and produces 10 dB less noise."

Because of the good experiences with the double air hose from Phase 1, these were also desired in Phase 2. "Single air hoses cause rotations between the crops that should actually be avoided. This is possible with the double air hoses. Combined with very economical EC fans you create a perfectly homogeneous climate and low operating costs."

New and existing

The system can be installed both in new and existing greenhouses. At RedStar, the hoses are used to control fogging, and for every fourteen gutters, three hose/ventilator combinations are installed. The EC's engine is wireless, and can be set to a continuously variable RPM and start-up time. "That means you can set the RPM yourself and set it to any given setting. With a start-up time of 120 seconds to go to 100% rotation, you can slowly inflate the hoses, which is good for durability."

For more information:

Enerdes – Sustainable Energy Solutions

Plesmanweg 17

7602 PD Almelo

Netherlands

Tel. +31(0)546 - 876 529

www.enerdes.nl