For a few months, George de Groot has been working together with Houdijk den Boer, a Dutch company that designs and manufactures cultivation floor systems for nurseries and propagation greenhouses. They have developed several solutions for the grower who is in search of a cultivation floor that decreases pest pressure, increases uniform growth and optimizes overall fertilization and irrigation. De Groot teamed up with Houdijk den Boer to introduce their systems to the North American growers, who increasingly realize the benefits of these irrigation floors compared to concrete ebb and flow systems.

First installments

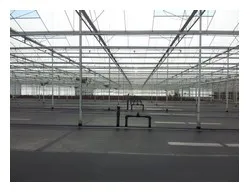

In July this year, De Groot will be installing such a cultivation floor system on 2 hectares at a grower in Beamsville, Ontario. Several other projects are already planned as well. According to George, the addition of the cultivation floor systems enables his company to offer a more complete solution. "We do not offer just one service or product, but a more complete package. We are involved with the job from the start, and whatever the grower is looking for, we listen to his needs and are able to offer a tailor made solution. Our experience with preparing the ground with laser grading and excavating tasks enables us to create a perfect floor that is precisely leveled. With the knowledge and supervision from Houdijk den Boer, a perfect cultivation floor can be realized, all according to the wish of the end user. On top of this, because we are located in Canada, we are able to source many materials locally, we know the local rules and regulations, which again gives us a head start."

Currently George de Groot is busy with the groundwork at the expansion of Kamps Hydrangea in Vineland Station, Ontario

Porous stone

The cultivation floors installed by De Groot are based on a standard ebb an flow system, but they are built up as a sandwich system. On top of a ground cover, porous stone material is responsible for a quick and equal drainage of the irrigation water. The upper layer, on top of the porous stones, is a strong, UV stabilized tarp. The combination of the porous stones, the upper tarp and the drainage system with automatic valves and pumps will ensure that the crops are irrigated equally and that the water will run off immediately after the irrigation round. No excess water will remain on the top layer, which results in uniform growth and fewer diseases.

The cultivation floors installed by De Groot are based on a standard ebb an flow system, but they are built up as a sandwich system. On top of a ground cover, porous stone material is responsible for a quick and equal drainage of the irrigation water. The upper layer, on top of the porous stones, is a strong, UV stabilized tarp. The combination of the porous stones, the upper tarp and the drainage system with automatic valves and pumps will ensure that the crops are irrigated equally and that the water will run off immediately after the irrigation round. No excess water will remain on the top layer, which results in uniform growth and fewer diseases.The floors can be installed inside greenhouses, but also as outside container fields. Depending on the crops and purpose, the material for the system is selected. Either basalt stones or lava stones can be used, in order to create the optimal drainage.