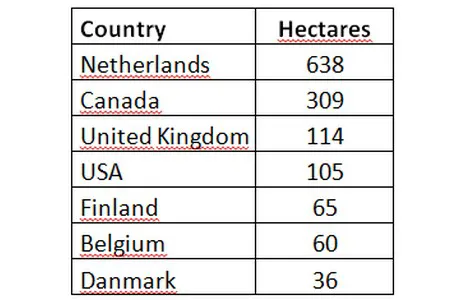

Holland and Canada are the countries where cucumbers are grown the most in high-tech greenhouses. (see table below)

Figure: Areas of high tech greenhouses growing cucumbers. Source: International Greenhouse Vegetable Production Statistics 2014

The productivity is very high and the best growers are able to produce 700-800T/hectare, so 70-80 km/m2.

This means that the plants grow several meters and therefore they need to be held with twine, in order to be able to grow vertically.

Traditionally, cucumber plants were held using plastic clips, or they were just twisted around the twine. Sometimes, especially in summer time, it is not easy to twist the plants and there is a high risk of breaking the head of the plant, therefore reducing the production. In addition, the twisted stem of the plant increases the stress and makes it more difficult to take in water and nutrients from the roots of the plant.

Typical high-tech glasshouse growing cucumbers in Holland with the high wire system.

Three years ago, Agrifast started to do some trials in Holland with the Tom System, a new electric tying machine, originally designed for tomatoes. The main difference with the plastic clip method is the material: the Tom System clips metal rings.

As it was designed for tomatoes, the inner diameter of the metal rings were 21 mm, the same as plastic rings for tomatoes.

However, the stem of the cucumber plant is thinner than the tomato plant, and therefore the cucumber plastic clips have a diameter of 14 mm.

Cucumber plants growing vertically and held by the metal ring of the Tom System.

This is the reason why in the beginning cucumber growers thought that the metal ring of the Tom System was too wide and therefore unsuitable for the cucumbers. Until the 2014 season, the Dutch grower Jan Reijm started a small trial: “I thought that it could work, so I just wanted to see for myself. First we tried just one row, to see if there was any damage to the crop, and after that several more rows, to see how the system was performing when lowering the plants.”

One metal ring every 40-50 centimetres is enough to hold the plants.

When Jan Reijm confirmed that technically it was working, he then concentrated on speeding up the clipping process. “We were used to plastic clipping with a speed of 1000-1200 plants per hour. When we started with the Tom System, at the beginning it was about the same speed. But after few weeks on the tools, our workers started to get used to it, and every week they were getting faster and faster.”

In order to increase the speed, it was crucial to use a weight balancer. Meaning the tool is held by a metal wire and the worker doesn't need to carry the weight of the tool for 8 hours a working day.

At the end of the season, they have been able to clip 1500-1600 plants/hour, and therefore reduce labour costs. Tying the plants is one of the tasks which requires more labour, as it has to be done every single week of the growing period and in summer times much more frequently, even every 3-4 days. This is the reason why an increase of 25-30% in clipping speed can provide great savings in labour costs.

There is not any crop damage being caused by the metal ring.

After the first positive experience in Holland, many growers from Holland and other countries have shown their interest in switching to the Tom System for the 2015 season. “We always prefer to ask the growers to try it themselves with their workers, but the enthusiasm is so big that sometimes they just want to start using the system even without running a small trial beforehand”, explains Dirk-Jan Haas, manager of DJ Products and exclusive agent of the Agrifast Tom System in Holland.

Detail of metal ring holding a cucumber plant.

“Most of the high wire cucumber growers are finishing the season now, or they are about to finish the season, so it is the time for decision making for the next crop. Then is when we try to advise and help them, as switching to the Tom System could save them several thousand Euro per hectare. And everybody knows how tight the numbers of the horticultural sector are in recent years, so every cent counts”

For more information

DJ Products

Dirk-Jan Haas

T: +31 6 59 69 56 54

Email: dj.haas@agrifast.nl

www.dj-products.com

Agrifast

Alberto Lizarraga

Email: alberto.lizarraga@agrifast.es

http://www.thetomsystem.com/