On Saturday, just before the Easter weekend, strawberries could finally be picked at VieVerde in Castenray. Like many growers, the first strawberry harvest took longer this year after a dark March. With the start of the red fruit harvest, harvest registration and the packing of various boxes also begins. For both time and kilogram registration, grower Ed Classens chose the ProCC system about five years ago.

The first strawberry harvest at VieVerde.

New shed, new sales organization

In Castenray, VieVerde grows strawberries on 1.5 hectares, in addition to 5 hectares of cucumbers. Ed has been running the greenhouse farm since 2008 after taking over from his parents. Step by step, the farm grew to a total of 6.5 hectares. A series of picture frames in the canteen give a nice historical picture of the growth process.

Machine line in the new cucumber processing shed.

During the last step of growth, in 2020, the grower invested in a new shed. A sixth frame is still ready to be hung. The shed is busy processing cucumbers in the week before Easter, using an extensive packing line where a fully automatic crate unfolding machine with depalletizer and automatic roller conveyor is the latest addition. The cucumbers go to customers via Kompany. So have the strawberries as of this year, after a foray for strawberries at another marketing organization in recent years.

Almost time to harvest.

First harvest

At VieVerde, the strawberries do not enter the new shed after harvesting. They are packed directly in the greenhouse and then go into the cold store. A few days before Easter, Ed has the carts of boxes ready in anticipation of the harvest. "I have the blue trays ready, but it's a gamble. The customer may still ask for another box." The first ripe fruits of the Malling Centenary variety are not yet yielding a very large harvest, but the start is there.

In both cucumber and strawberry cultivation, there are peaks in production. At those times, VieVerde can use the help of a group of permanent and flexible employees, including quite a few schoolchildren. There are around 40 in total, with not everyone working full-time. Foreign employees who come to help in cultivation, VieVerde can offer accommodation on its own premises. "We work with a lot of experienced people, with some of the foreign employees also coming back after the winter," he says.

Grower Ed with, for those who look closely through the glass, the electricity pylon around which the greenhouses in Castenray are built.

Insights from registration

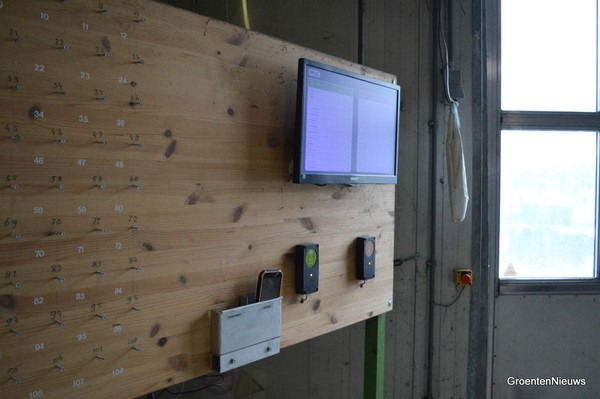

The grower started using ProCC's time-recording system about five years ago. A dashboard for this is still displayed when entering the greenhouse. "Our desire was to get more data from the greenhouse, partially to be able to check if the work is done properly. Previously, we also recorded labor, but only time and not specifically the operations."

Using ProCC's system, which works with apps and smartphones for registration, the grower has a good overview of the work in the greenhouse. Moreover, the data from the greenhouse provides him with important insights into where labor is going on his mixed farm. How much labor goes into growing strawberries and how much into growing cucumbers, he can now clearly see. Also useful when doing trials. "We don't want extra labor when growing a new variety," he says.

ProCC works with apps and smartphones and scanning a tag on the gutters.

Specially for strawberries

Time and labor registration and kilogram registration work separately, but the data eventually converge in a platform. The piece of software for kilogram registration was made by ProCC specifically for VieVerde, following a request from Ed. When VieVerde started working with ProCC's system, registration for strawberries was still under development.

"We do quite a few trials with new varieties, and so we also wanted to be able to keep track of kilograms. With new varieties, production still tends to lag behind." Registering kilograms can be done by VieVerde with ProCC's software for strawberries, which also have a lot of different types of trays. "Wooden trays, blue trays, transparent trays," lists the grower.

VieVerde conducts trials where kilogram registration is important to determine whether a variety has potential.

Bonus reward

Employees scan a tag when entering a row and also scan again when exiting. Then they enter how many crates they have filled. Based on fixed data and selecting the type of cask, the system then calculates how much has been picked. "We now also see who picked which kilos. This allows us to work with bonus rewards for employees."

In the shed at the front of the farm, all the barrels are ready for a new season. The cucumber processing line that was also there before is now in the new shed. "We have filled in the extra space we have as a result, among other things, by mainly putting the silos with water supply inside."

Time recording when entering the greenhouse.

Harvest forecasting

A new development that VieVerde is also looking at is harvest prediction. The data from registration via ProCC provides growers with better insights about the kilos, but when it comes to harvest prediction, growers still mainly do that based on looking closely in the greenhouse and experience. Students from Fontys and HAS University of Applied Sciences are testing harvest prediction in the greenhouse in Castenray. The first steps for this were taken two years ago. "Back then, the focus was on making good camera images. This season, the test will get a follow-up."

For more information:

Ed Classens

VieVerde BV

Roffert 8

5811AT Castenray

Tel.: +31 (0) 622661288

info@kwekerij-vieverde.nl

ProCC

info@procc.nl

www.procc.nl