Professional Horticultural Consulting is a strawberry nursery and production facility in South Africa with an acreage of 70 hectares. They supply their strawberry plants to growers across the country, and they’re also the largest exporter of fresh strawberry fruit in the southern hemisphere.

The issue they faced was that the water in the area was endemic to Phytophthora infections. “It’s very important that we have a clean water supply going to the nurseries so that we don’t get Phytophthora infections in the nursery and lose plant material or substandard supply plants to the growers,” says Gavin Linsley Noakes, the company’s CEO, and co-owner. Previously the facility was using industrial peroxide, which struggled to control plant infection. Industrial peroxide has a limited purity due to the production process at large chemical plants and contains stabilizers that limit the reactivity of the pure hydrogen peroxide – thereby having a weaker effect on pathogens.

Peroxide UltraPure™, generated by the HPGen™ system, is intrinsically stable and safe for agricultural use. Additionally, the use of Peroxide UltraPure eliminates the occupational hazards involved in dealing with high-concentration bulk peroxide, and it is highly sustainable, being made directly on-site from only water and electricity, without any chemical inputs.

Lower disease pressure, improved plant health

The grower decided to have an HPNow system installed, which generates Peroxide UltraPure through a patented electrochemical process that yields the highest purity available in the market, >99.999 %. This had a threefold effect:

- Plants were protected from water-borne pathogens, such as Pythium and Phytophthora.

- Irrigation became more uniform, with Peroxide UltraPure dislodging a good amount of biofilm thanks to its stronger reactivity, and Botrytis outbreaks were virtually eliminated from the facility.

- Dissolved oxygen content in irrigation water also increased by 3 ppm, as peroxide was activated easier without a stabilizer. This meant a more robust root system and improved plant health.

1,5 million plants saved

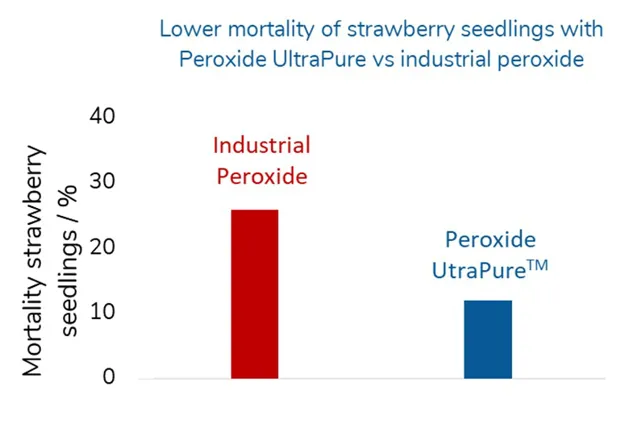

“In the strawberry industry, the biggest threat is water- and soil-borne root diseases. The Peroxide UltraPure reduced the mortality rate,” Gavin explains. “Because it runs continuously, the Peroxide UltraPure makes sure that the root system doesn’t come into any contact with either Phytophthora or Pythium or any other water-borne root disease that affects strawberries.”

With the HPNow system in place, the grower has reported lower plant mortality compared to the industrial peroxide that was used before: from around 20 percent, and it went down to 10 percent. “If you convert the 14 to 15 million tray plants that we’re producing, that’s 1.5 million plants saved.”

For more information:

HPNow

sales@hpnow.eu

www.hpnow.eu