Most people associate vineyards with serenity and tranquility. To a grower, vineyards can represent the opposite: High establishment costs, labor-intensive management, and deadly disease avoidance over the decades-long lifespan of a vineyard.

Researchers at the Department of Horticultural Science at NC State University in Raleigh are working on changing a fact that has shaped the industry for over 5,000 years: Grapes are a perennial crop. In collaboration with Current, the researchers are working on a project which might fundamentally change the way grapes are grown in the future: A grapevine that can be planted and cropped in the very same year.

Pictured: Dr. Mark Hoffmann (left), PhD student Kyle Freedman (center), and Research Associate Cristian Collado (right).

Pictured: Dr. Mark Hoffmann (left), PhD student Kyle Freedman (center), and Research Associate Cristian Collado (right).

Understanding grapevine cluster development is key to their research. Like many woody plant species, grapevine clusters develop over two seasons. The development of inflorescence primordia (the early developmental stages of a group of flowers) happens in the first year within the dormant buds on the vine. Bud break and the development of the grape clusters happens in the second year, usually after a period of dormancy. Those grape clusters bear the fruit that we all enjoy, be it fresh, as juice, or as wine.

The dilemma is that a mature grapevine must develop inflorescence primordia for the next season, while developing fruit for this season. Optimal conditions for primordia development are not necessarily the same as for fruit development. High temperatures, moderate to low nitrogen, and high light intensities are important to develop inflorescence primordia, while the same factors can hinder achieving high quality fruit. This puts vineyard managers and grape growers into a difficult position every year, with growers often deploying costly and lengthy cultural management methods.

The researchers’ aim is to develop a system in which a grower can focus on growing the fruit without worrying about next year’s crop and finding the optimal conditions for the floral development of a grapevine transplant.

Results

Researchers identified the optimal environmental recipes under which a vine develops the greatest amount of inflorescence primordia, and eventually clusters. Using Arize® Element L1000 lighting, they investigated the impact of different light intensities on primordia and cluster development (Figures 3-4). Because grapevines are conditioned in an indoor environment, using precise light intensities, it is called Precise Indoor Vine Conditioning, or PIVC for short. The advanced Arize LED lighting provided by Current was key in maximizing conditions for the grapevines in the greenhouse. The lights are programmable through a computer, allowing specific light intensities (amount of light), and durations of light exposure (photoperiod).

Figure 2: Arize Element L1000 LED fixtures over grapevines in the NC State University Greenhouse Complex.

Figure 2: Arize Element L1000 LED fixtures over grapevines in the NC State University Greenhouse Complex.

Kyle Freedman, a 2nd year PhD student, shared his enthusiasm: “This lighting system has made it possible for us to conduct this state-of-the-art research and to really push the boundaries of the amount of light intensity we could apply. Other systems would have limited our capabilities and prevented us from exploring this proof of concept” (Figure 2).

Kyle explained that the purpose of a controlled environment with advanced lighting is to give the grapevines ideal conditions to promote growth and development. During nursery production, young grapevines experience a wide range of environmental conditions, such as reduced light from shading and cloudy days to temperature fluctuations, which can inhibit maximum growth and development. Kyle indicated that “While we don’t anticipate a shift from vineyard-grown grapes to greenhouses, we do believe this system could provide new methods of nursery production and supply growers with stronger plants that could yield harvestable fruit earlier”.

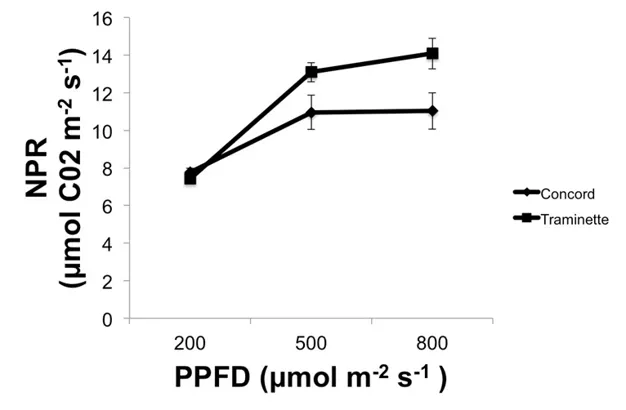

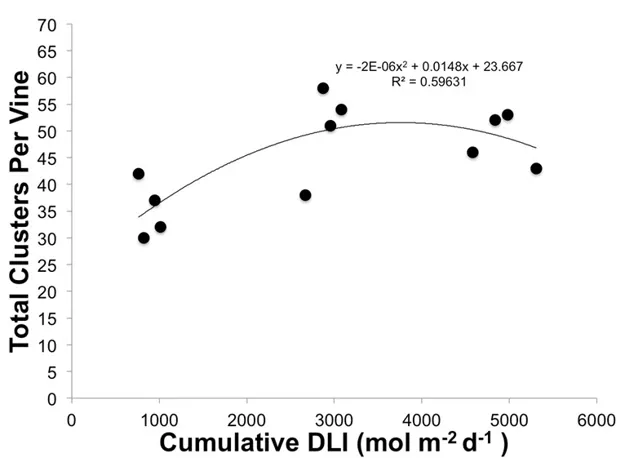

Results from the light conditioning phase of Kyle’s research show that the net photosynthetic rate increases significantly for the cultivar ‘Traminette’ moving from low to high supplemental light intensity and from low to medium for ‘Concord’ (Figure 3). This is important as not all plants can process additional amounts of light for photosynthesis, which is essential for increasing fruiting capacity. In addition, clusters were counted after vines were transplanted in a local North Carolina vineyard, with the highest cluster counts observed at medium supplemental light intensity (Figure 4). These results show promising advancements in this research as optimal light intensity to increase fruitfulness was determined and can be tested on future cultivars. The next steps in Kyle’s research include investigating the impacts of container size on root development as well as evaluating the whole system’s economic feasibility

Net photosynthetic rate of ‘Concord’ and ‘Traminette’ grapevines in response to different light intensities  Figure 3. The net photosynthetic rate was measured using a LI-COR LI-6800 portable photosynthesis system. Light intensities used to measure net photosynthetic rate (NPR) included average solar radiation transmitted through the greenhouse plus supplemental light treatments.

Figure 3. The net photosynthetic rate was measured using a LI-COR LI-6800 portable photosynthesis system. Light intensities used to measure net photosynthetic rate (NPR) included average solar radiation transmitted through the greenhouse plus supplemental light treatments.

Effect of cumulative DLI on the number of ‘Traminette’ clusters  Figure 4. ‘Traminette’ clusters were counted 2 weeks after bud break and regressed with cumulative DLI from the previous season’s greenhouse conditioning. The average cluster number per vine significantly increased from no supplemental light to 300 PPFD, at which the average cluster number was the highest.

Figure 4. ‘Traminette’ clusters were counted 2 weeks after bud break and regressed with cumulative DLI from the previous season’s greenhouse conditioning. The average cluster number per vine significantly increased from no supplemental light to 300 PPFD, at which the average cluster number was the highest.

Conclusions

Imagine grape growers being able to choose new cultivars every season, without having to wait three to four years before harvesting the fruit. Imagine an annual vineyard in Central Canada that produces fresh local grapes every summer. Imagine how adaptive a system like this would be to climate change, but also to consumer demand and for breeding purposes. While these scenarios may seem far off in the future, NCSU and Current are laying the groundwork today.

For more information:

Current

gecurrent.com