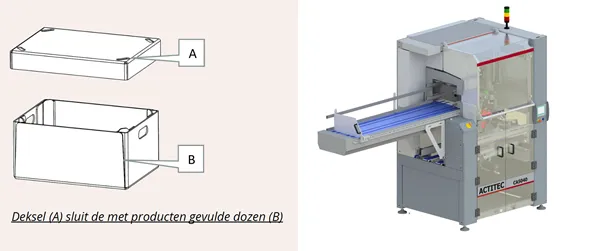

The market wanted a machine that could take over the time-consuming task of manually placing preformed lids on boxes. Besides it taking people a lot of time to do, producers have recently had to deal with those people simply not being available. Staff shortages are commonplace. That is why, in Europe, Actitec, Sarco Packaging's service partner, developed the fully automatic CA5040 lidding machine. It accurately places lids on boxes filled with fresh products like fruit, vegetables, meat, and fish.

Albert and Sander with the machine.

Improved efficiency

The lidding machine now does the laborious manual task of folding and placing the lids. "The process is fully automated, thus improving efficiency tremendously. Not only does it save time, but this machine also clearly improves occupational health and safety - there is no longer an often repetitive action."

"Also, when lids are folded and placed by hand on boxes, some room is deliberately left between the box and lid. That makes it easier for the worker to place the lid. The machine needs less space between the box and lid. That is a vital added benefit. The lids stay put better, and the filled boxes stand more firmly on the pallet."

The lids are almost all 30 x 40 cm to 40 x 50 cm, but larger ones can be processed too. This mechanically intermittent machine can lid up to about 1,500 boxes per hour. That capacity depends on the mix of boxes and crates. The machine can detect crates, which it does not lid, only passing them through.

Industrial and compact machine

Thanks to its compact size and straightforward connection, this lidding machine can easily be integrated into an existing packaging line. Actitec can assemble the machine to customer specifications. The cardboard lid magazine can be placed on either side of the machine. Once lidded, the boxes are fed out of the machine.

The lidding machine at work.

This machine has state-of-the-art technology and can be remotely serviced via the internet. That ensures a reliable machine that is ready for the future.

For more information:

For more information:

Wahid Payanda

Sarco Packaging

21 Rondgang

5311 PB, Gameren, NL

Mob: +31 (0) 648 584 619

Email: w.payanda@sarcopackaging.com

Website: www.sarcopackaging.com