The time when robots are widely available for every grower hasn’t yet arrived, but that doesn’t mean that some growers aren’t already betting on such innovative solutions. Dyson Farming, located in the UK, has invested in a UV light robot to improve the efficiency of their glasshouse enterprise, directly affecting the crop they grow. “It’s a novel solution,” agrees Angel Angelov, Glasshouse Manager at Dyson Farming. “The technology is still in its infancy; we are one of the first commercial businesses to take advantage of this particular type of robot. We considered the ROI and decided that it was worth the risk of early adoption to employ such a system within our business.”

Innovating from the get-go

Angel and Dyson Farming are not afraid to undertake challenging projects. Their greenhouse project already made the headlines a couple of years ago when construction began in early 2020. “Adjacent to the greenhouse is an anaerobic digestion plant that is powered by the crops we grow on the farm. Including these energy crops in the rotation not only provides heat and power for the glasshouse but also gives agronomic benefit to our arable cropping system,” he explains. “This off-grid power supply allows us to provide warmth and light to our strawberry crop outside the summer growing season.” This means that Dyson Farming is less affected by the rising energy costs since most of the infrastructure’s energy requirements are delivered via onsite renewables.

Riding the wave

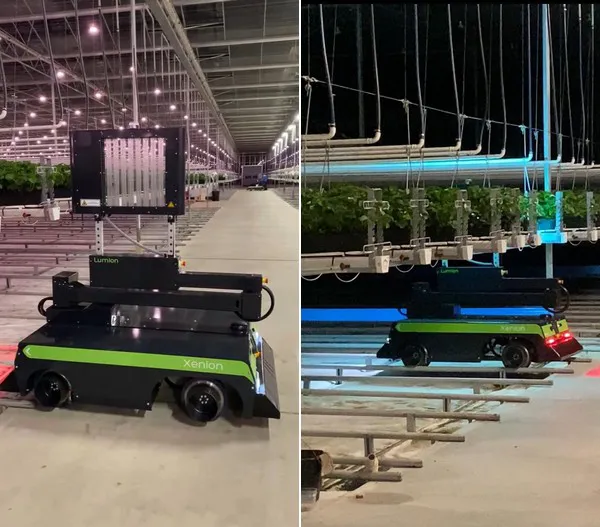

When a greenhouse project starts so impressively, no wonder Angel and Dyson Farming wanted to keep riding the wave of innovation. “The UV-light robot is part of that story,” he says. “At Dyson, everything is about quality and sustainability, and we are committed to continually measuring our own performance. Environmentally sensitive plant protection is a key part of our strategy.” In their greenhouse, Angel and Dyson Farming grow strawberries. “Everyone in the UK loves strawberries, they are quintessentially British, and provenance is important to consumers. Growing soft fruit out of season poses a number of challenges including the control of pests and powdery mildew. The UV-light robot, which uses UV-C light to break down the DNA of disease, complements the use of biologicals to control aphid numbers.”

Prolonged exposure to UV light can be dangerous to human health. “The automation of the robot overcomes this problem,” Angel says. “The robot can be programmed and remotely controlled through a mobile app and therefore left to operate overnight while the area is clear of people. So far, it has been working efficiently. We are hoping to significantly reduce the amount of inputs normally required to keep powdery mildew at bay.”

Financial feasibility

One of the main concerns of utilizing a robot is the high upfront cost. “Of course, opting for such a solution needs to be financially viable,” Angel points out. “To appraise the investment, we compared the cost of chemical input over the same number of years as the expected life of the robot. The ROI figures were acceptable when considering not only do we save on inputs, but we also save on labor costs. Admittedly, the return is long term, but as long as a business has the capital to invest, solutions such as the UV light robot will be explored.”

As said, Dyson Farming is currently growing strawberries but is planning to expand its soft fruit portfolio. “There are a few key stages ahead of us,” Angel explains. “We are just coming to the end of phase 1. We want to keep innovating and look at how we can better utilize our resources, be it growing in different ways or at different times of the year. We have a good team of engineers working to develop advanced systems, and I am sure that our future will look very different from what you see now. The current project is just the start.”

For more information:

Dyson Farming

dysonfarming.com