The ongoing and costly global shipping crises impacting the cold chains of the fresh produce industry, from Europe to the US to China, as well as across South America, Africa, and Oceania, is predicted to continue for some time. “It also caused a rapid shift to the increased uptake of smart data loggers that allows more insights into cold chain monitoring with new additions, like pack house monitoring right down to predicting the remaining shelf life of produce,” according to Joel Uzan EMEA Territory Manager for Xsense®.

He summarises the past two years and recent global developments affecting cold chain management: “With the global lockdowns, and longer transit times of shipments of fruit and vegetables, cold chain smart monitoring really came to the fore. Ports became congested. Containers were often unavailable. Cargo that had traveled in passenger aircraft didn’t. Some cargo shifted from air to sea, but sea freight became unreliable. There was an increase in the use of conventional reefer vessels. Transport times increased. Produce was redirected to different markets. The conflict in Ukraine changed food supply chains into that country: more vehicles and less vessel traffic. Efficient and timely cold chain monitoring visibility, allowing for swift intervention when needed, became even more relevant under these circumstances,”

“The turmoil of the last two years has only increased the level of monitoring and accelerated the shift to smart data loggers (wireless or cellular) for automatic and real-time reporting of data. Many customers have become willing to pay much more for their monitoring based on the perceived increased value. Also, new users within organizations are accessing and utilizing the data; and those users may attach a higher value to the information. Our customer base has typically taken cold chain monitoring seriously; it is one of the reasons they select Xsense over alternatives,” explains Uzan.

Does the use of smart loggers save money?

He says smart loggers don’t necessarily save money. It all depends upon how the loggers and the information from them are used. “Their use may be integral to providing a premium product which commands a better price, rather than saving money. Insights derived from logger data, smart or otherwise, may be limited to the items being monitored, or may have long-term implications, such as changes in processes, operating parameters, training, and selection of service providers,” says Uzan.

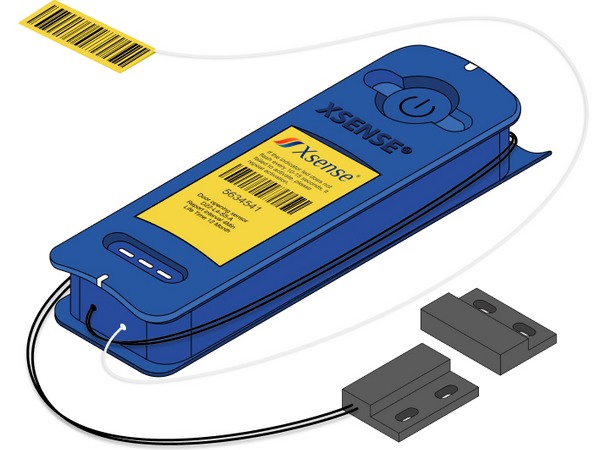

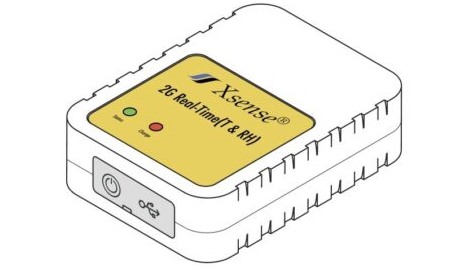

Xsense® with its headquarters in Migdal Tefen, Israel, is a provider of smart monitoring solutions for all parts of the cold chain: at origin (field, factory, pack house), in transit (air, sea, truck, or rail), at destination (supermarket, retailers), and at points in between (ports, terminals, DCs). They are one of the early pioneers in the application of wireless data loggers to the cold food chain.

“Our loggers are designed to work in environments where other technologies find it difficult to operate while remaining affordable. Our solutions are focused on the reduction of waste and extension of shelf life via the provision of timely information and metrics. Due to our original solution comprising wireless loggers connecting to wireless gateways, it was necessary to build a solid software framework to complement our hardware. This legacy continues to this day. Our customers continue to tell us that one of the reasons they select us is due to our solid and capable software platform. We can provide complete segmentation and real-time location tracking. Information is accessible via a mobile application, web application, or received via email, alerts, or SMS messages. We expose the information to the owners of the data, and those granted permission to see it, only.”

He says while they have no insight into when the shipping delays will return to normal schedules, smart cold chain monitoring will play an increasingly bigger role for everyone in the value chain.

Will shipping return to normal?

“We did hear from a shipping broker that vessel lines were likely to run their vessels slower rather than remove capacity as new vessels come on stream. So, longer shipping times may be on the cards. Services, infrastructure, and monitoring devices are, bit by bit, being put in place to make it easier to better understand and control the condition of goods passing through the cold chain. These systems deliver timely information, which enables operating to tighter tolerances, and quickly initiating corrective actions when necessary, and if not possible, prepare for the eventual outcome. Examples are a shipper retrieving a failing reefer container from a port prior to loading on a marine vessel, maintaining tight tolerances on the cooling of individual pallets of produce over multiple days, pulling pallets for inspection that have been dropped too abruptly (shock sensor). Smart monitoring comes down to better knowing one’s business,” Uzan states.

He says it is not clear what the 2G replacement will be for the Internet of Things. “No cheap universal alternative has taken hold. So, cellular monitoring connectivity will likely get less reliable or more expensive. We are expanding our hardware portfolio and are looking forward to introducing some innovative products over the coming years,” he concludes.

For more information:

Joel Uzan

Xsense®

Tel: +972-(0)4-9122826

Email: joelu@xsense.co

www.xsense.co