The herbal trend is unbroken. Whether as potted goods for the fresh kitchen, as part of the indoor herb garden, or as a special feature in the balcony box.

Promote growth and aroma

The amount of potted herbs and freshly cut herbs produced in Germany is constantly increasing, as is the interest in buying new herbs and varieties. Fresh herbs, especially potted goods, have become indispensable in the kitchen. It is all the more important to position yourself as a manufacturing company on the market with exceptional goods and special quality.

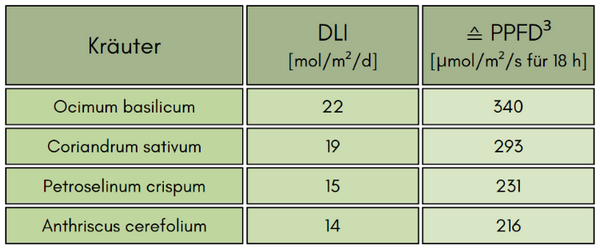

The herb varieties, which often come from warm climates, not only place high demands on the prevailing climate but can also be controlled in terms of their quality, above all through light intensity and spectrum. A significant increase in quality is achieved through the use of modern additional exposure with light sums (DLI¹) of 12 to 15 mol/m²/d.

Control of fungal diseases

Fungal diseases play a special role in herb production, as they can quickly lead to a complete loss of production. FUTURELED was the first company in the world to develop a light-based solution that allows the proactive containment of fungal spores on and in crops without having to use fungicides. The right light is crucial! This makes it possible to combat fungal spores and other pathogens in the long term without restricting the growth of the plants.

If used regularly, the number of germs in the stock can be reduced below a harmful level by using the FUTURELED SporeCleaner, thus preventing an outbreak in the stock. Even after an outbreak, the system can be used after removing the diseased plants from the stand, to disinfect the plants and reduce the germ pressure to a minimum. In this way, a further infection can be effectively prevented. The use of the SporeCleaner is harmless to the environment and can be carried out in the greenhouse without hesitation.

The light sums to be achieved

In herb culture, compact growth and a convincing aroma are important quality features that can hardly be achieved without sufficient light. Fresh potted herbs are in demand in large quantities, especially in spring and winter. So early in the year, the right assimilation exposure makes all the difference.

In principle, many herbs can also be cultivated without assimilation exposure, but the quality drops sharply. In this way, 7 mol/m²/d can be defined as the minimum lower limit of the light sum. For many herbs, the amount of light has a much stronger influence on quality than the prevailing temperature or fertilization. A light sum control based on the PAR² radiation has a direct influence on the quality of the herbs produced.

LED lighting systems in use

The right amount of light makes all the difference when it comes to herbs, helping to promote both high quality and quantitative production alike. Under optimal light levels, a higher firmness of the shoot axis and compactness is achieved and a significantly improved aroma is also recorded. At the same time, vitality is promoted and stress tolerance is improved. The latter is particularly important for the production of organic potted herbs.

Also used are perennial or woody herbs such as Lavandula angustifolia (lavender), Artemisia dracunculus (tarragon) and Rosmarinus officinalis(rosemary), assimilation exposure has a particularly positive effect on growth and aroma, as our studies in cooperation with the Julius Kühn Institute have shown. In addition to significantly increased growth of up to 150% compared to conventional exposure, the valuable ingredients could also be significantly increased.

For more information:

For more information:

FUTURELED GmbH

https://futureled.de