Leo Uijtdewilligen of Vergo Kwekerijen grows sweet pointed peppers on 7,5 hectares in Belguim. He also packages these peppers. Leon was looking for a more efficient packaging system. He has found it.

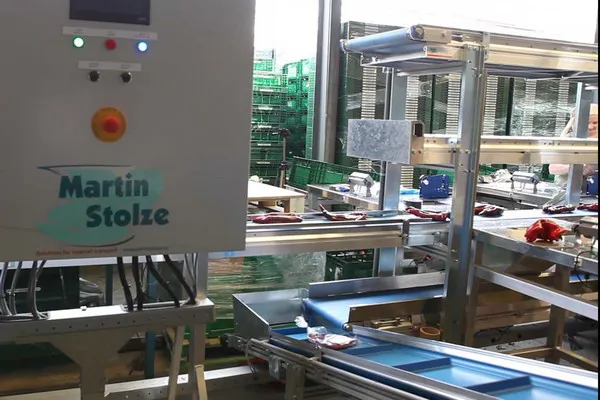

The Dutch company, Martin Stolze, installed the packaging line at Vergo Kwekerijen. The grower uses it to package the peppers in bags and flow packs. Peter van der Knaap, Martin Stolze's account manager, supervised the process. "The line is equipped with LRE scales. Also, each workstation has a counting system. That gives a better overview of the processed quantities. The system consists of four levels," he says.

More efficient

A conveyor belt brings the containers of harvested pointed peppers to the workstations. There, employees weigh and pack the peppers. The pointed bags slide in a tube to the lower conveyor belt. A feed belt transports the peppers to a turntable. There, workers pack the bags into boxes.

At the same time, at the workstations, the staff place some pointed peppers on a different conveyor belt. This brings the peppers to the flow packing machine. The packaged peppers arrive on another turntable. There, again, employees pack them into boxes. The workers can dispose of the empty harvest containers via roller conveyors.

"Packaging the peppers has become more efficient since the system was installed. That also reduces labor costs," Leon concludes.

For more information:

Peter van der Knaap

Martin Stolze b.v.

6 Leemidden

2678 ME, De Lier, NL

Tel: +31 (0) 622 489 009

Email: peter@martinstolze.nl

Website: www.martinstolze.nl