In recent years, supplies of greenhouse grown leafy greens have gone up in rapid pace. Although this is a global trend, the growth rate is highest in the United States. “Popularity of greenhouse grown produce is driven by factors like year-round supplies, efficient use of water and labor, less dependence on climate changes, protection against extreme weather events, reduced risk of diseases, lower pesticide use and a higher ability to control the end-product,” says Joost Somford with JASA Packaging Solutions. “In addition, COVID-19 is playing a role as well. Import and export restrictions caused by the pandemic have further increased the popularity of greenhouse grown produce as it reduces the dependence on imports.”

Within the United States, the greenhouse category is expanding across the country, but the growth rate seems particularly high in urban areas. With reduced travel distance and travel time from field to store, greenhouses not only provide high-quality produce in big cities, but also play a key role in security of supplies. As a result of growth in this category, demand for high-quality packaging solutions is up as well.

Sleever for leafy greens

Sleever for leafy greens

Camera systems and quality control

JASA Packaging Solutions was established in the Netherlands in 1985 and the company opened a branch in the United States three years ago. “From day one, we noticed strong demand for flexible and innovative packaging lines for greenhouse grown produce, from the East Coast to the West Coast,” said Somford, who installs packaging lines nationwide as well as into Canada. “Being a Dutch company plays to our advantage,” he continued.

The Netherlands has always been a front runner when it comes to the greenhouse industry and the country has built a strong reputation over the years. “As a result, we have been supplying packaging solutions for the greenhouse industry for all 35 years we’ve been in business.” Decades of expertise allow JASA to offer new solutions next to the proven tray packaging lines that weren’t available in North America until now. An example is the use of camera systems to control seal density, as well as positioning of the labels and the prints of lot codes and dates on the labels. In addition, the company offers a variety of options when it comes to product quality systems. An example is the use of UV-C technology inside a protected environment. Bacteria and viruses are quickly deactivated with UV-C light. The working of UV-C is one of the new proven technologies in product controlling.

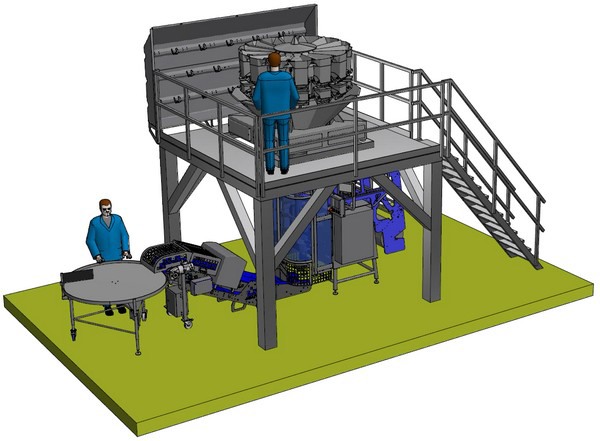

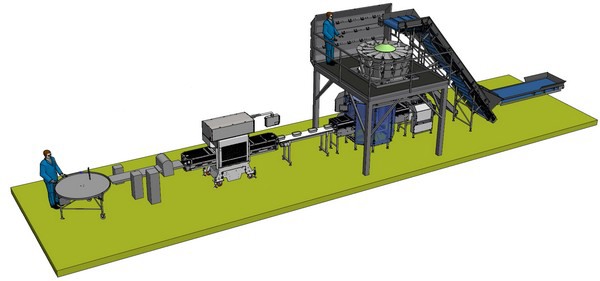

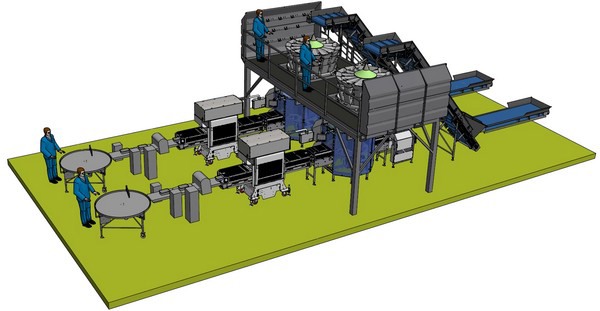

Since this type of equipment is not being widely used in North America yet, JASA often collaborates with Dutch partners in offering a complete, integrated packaging line. “We work together with greenhouse builders, but also companies that are experts when it comes to harvesting, washing, and mixing of product. “Our expertise is centered around packaging leafy greens and we also take care of the end of line, which includes palletizing and case packing. “We are able to offer support throughout the entire process and this is being appreciated by our North American clients. We are here to provide service to our customers from beginning to end.” Bag packing line

Bag packing line

Single tray packing line

Double tray packing line

Difference between packaging in North America and the Netherlands

Although customers in North America and the Netherlands can expect the same high-quality packaging from JASA Solutions, the look is entirely different. First of all, the size differs greatly. In North America, a package with leafy greens contains up to 500 grams (about 1 lb.) of greens while most packaging in the Netherlands contains about 100 grams of product. Not only do packages in the United States need to hold more volume, another difference is the type of packaging leafy greens are sold in. Whereas bags are the most popular packaging for leafy greens in the Netherlands, in the United States leafy greens are mostly sold in plastic clamshells or top sealed trays. “Popularity of trays is driven by the importance of design,” commented Somford. “A tray looks appealing on the shelf while a bag is still perceived less attractive. In North America, much attention is paid to the look and feel of the packaging.”

For more information:

For more information:

Joost Somford

JASA Packaging Solutions, Inc.

Tel: +1 (804) 290-3683

sales@jasapackaging.com

www.jasapackaging.com