How can one sort and package with food safety as a top priority? That question becomes increasingly important in the market, with consumers paying more and more attention to fresh produce hygiene. Greefa is rising to that challenge with the development of a new hygienic machine. Dick Verkade, Manager Marketing & Sales, would like to tell you all about it.

Extra clean

“We adjusted the design in such a way as to avoid build-up of dirt, and with that also the chance of bacteria growth. In addition, because of the open design with smaller, the user can now immediately see the presence of dirt, so he can start cleaning up faster and more easily.”

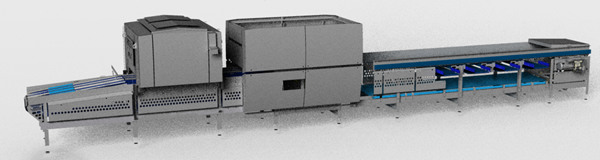

GeoSort Ultimate Clean

The new machine, which is intended for sorting round fruits such as apples, is based on Greefa’s original GeoSort. “We’ve kept the concept, but we redeveloped the design from the ground up, with more stainless steel and sloping surfaces everywhere so that dirt does not have a chance."

Clean machine

"For food safety, it’s essential that the machine itself is clean and won’t be a contamination source. While in the past brushes were often used, now they’re avoided due to potential contamination. What’s more, parts of the machine, like cups and diabolos, are automatically cleaned in the new GeoSort, without human intervention. “When employees are on their coffee break, the machine can go into a cleaning cycle, to prevent dirt from building up.”

"Cleaning the machine has been made easier in other ways as well. All electronic parts are shielded so that they can be cleaned with water. In addition, the camera box that contains the cameras can be lifted, so cleaning underneath it is a breeze."

Food safety takes center stage

With the upgrade, the company took another good look at all the parts: for example, are the plastic parts all suitable for contact with foodstuffs? “Another interesting thing: all turning parts in the machine need to be lubricated, but oil attracts dirt. That is why we have now applied chains that no longer require lubrication, through a combination of innovative materials..”

Prototype

At Greefa, they’re currently busy testing the prototype. The tests are looking good, and the plan is to launch the new machine in the market during the second half of this year. “After summer, it should be available to customers.”

For more information:

Greefa

Tel: +31 345 578 100

Email: info@greefa.com

www.greefa.nl