In September LC Packaging opened its new, sustainable, state-of-the-art head office and warehouse at the Logistiekpark A12 in Waddinxveen. A grand opening was not possible due to the Corona situation, but AGF.nl has been able to take a look at the new building of the family business that has been active in the packaging industry for generations.

Boudewijn van Fraassen and Nick Jansen

The great-grandfather of CEO Lucas Lammers started the company in 1923, with the sole activities of purchasing, reconditioning and distribution of (second-hand) jute bags. The company is now specialized in FIBCs (big bags), net bags, cardboard, paper, jute and WPP packaging for the fruit and vegetable sector and industry.

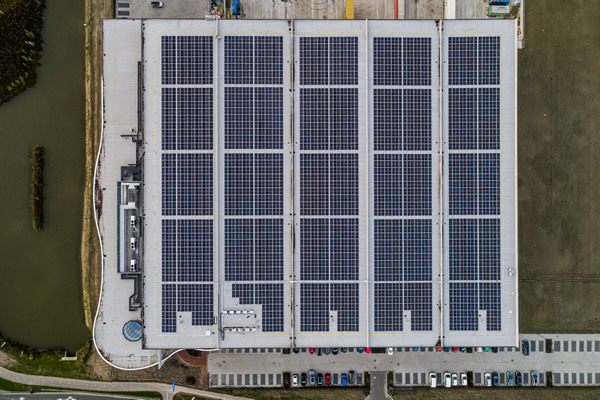

The new building is 16 meters high and has a total area of 12,500 m2 of warehouse and 3,000 m2 of office space. The warehouse in phase 1 has a capacity of 29,000 fully loaded pallet places with an additional hall for printing jute and plastic bags. In phase 2, 5,000 m2 of warehouse will be added. Sustainability and well-being were keywords during the construction, according to Nick Jansen (Director Europe). For example, there are 3,032 solar panels on the roof, enough to provide 386 households with energy for a year, and rainwater is collected and used by growers in the area.

"With the BREEAM Outstanding score, we are one of the most sustainable buildings in the Netherlands, but above all we want it to be a pleasant place to meet. By working together you promote cooperation between the different departments, both within the Netherlands and abroad, purchasing and sales, marketing and sustainability. Due to the current Corona measures, some things can't be helped at the moment, but we believe in coming together at the office. We do everything we can to ensure that colleagues work together in the most pleasant way in a fantastic workplace that is fully equipped and we want to be a knowledge center for each other and our customers. Transparency is paramount here, both to our suppliers and customers. We are happy to include them both in the process and also believe that this is the future."

The new building is therefore fully equipped with a real auditorium, a gym where colleagues can exercise under the supervision of a personal trainer, a spacious canteen where a fresh lunch is provided on several days, standing desks, consultation rooms and spaciously arranged desks with videophone. About 100 people work at the head office in Waddinxveen. Downstairs, the fifty colleagues of LC Netherlands are active, worth around about 50 million of the total 200 million turnover, whilst working on the top floor are the colleagues of LC International, the umbrella organisation that oversees the entire supply chain of the LC Packaging Group and maintains contact with all LC Packaging affiliates in Africa, Asia and Europe.

Anyone who thinks it will stop here is wrong, because LC Packaging has its own offices in Belgium, France, Spain, Portugal, Germany, Hungary, Romania, England, Scotland, Ireland, Sweden, South and West Africa. "And these are not sales offices with two people, but all decent offices with their own storage. Thanks to our SAP system we have a real-time view of the stock and we see all purchase and sales orders of the entire group," says Boudewijn van Fraassen, director of Agricultural Packaging.

"With offices, production facilities and warehouses in 16 countries in Europe, Africa and Asia with more than 1,700 employees, we are always close by and there is always a location nearby! Thanks to our storage capacity of over 70,000 m² and an extensive distribution network, we can guarantee our deliveries, even during seasonal peaks and for short-term deliveries," continues Boudewijn. With three offices in the United Kingdom and two offices in Ireland, Brexit has not caused major problems for the packaging supplier.

LC Packaging prefers to grow in depth rather than in width. "We would like to keep the focus. We are already active in a considerable number of sectors and that requires a gigantic stock and storage. For example, we sometimes have twice the turnover of a year on belt bales. But should an onion sorter suddenly demand from Central America or Asia, we can provide this. We therefore look for our growth mainly within the existing markets. We find it more important to be a top-3 player anyway and prefer to be the market leader in the markets in which we operate than do it as a little bit on the side."

The international office network came at the right time last Corona year. "The demand for our packaging rose very fast, but in the supply we, like everyone else, faced major challenges. We drove like crazy between the different branches to meet the demand of our customers. It has been quite stressful getting that done, but we succeeded, partly because we keep such an almost irresponsibly high stock for our customers," says Nick Jansen. "At the same time, the shortages do pose challenges. For example, the price of polypropylene (PP) granulate has increased by 40% in one month. I have never experienced that in the 25 years that I have been working for LC Packaging. The scarcity of jute and paper is alarming. It means you have to talk to your customers about the current contracts, because the customer has to get their packaging regardless."

"What does help in this is that we often work on the basis of long-term partnerships. Ten years ago we were much more active on a day-trade basis. Now we can guarantee many more long-term products to our partners. Thanks to the combination of our own factories and the semi-in-house production with partners, some of whom we have been working with for thirty years, we can guarantee quality and availability," says Boudewijn.

He does not see producers from the Far East who try to set foot in Europe themselves as competition. "That often seems like a good idea, but experience shows that these companies can never last in the long term. We believe that quality is much more than just the strength of our packaging. It's about the total picture. If you have nothing more than your packaging to offer, you won't make it. "

With jute packaging, LC Packaging already has a textbook example of compostable packaging, according to Nick. The company does not focus on the smaller, jute consumer packaging, which is on the rise, mainly elsewhere in Europe, because it wants to keep its focus on customers in the food & agri and industry.

Sustainability is front of mind at the packaging company. "For example, we have an alliance with Veolia to limit waste from flexible packaging worldwide. Recycled polypropylene (tPP) is also a hot item. This is already being tested by British customers. We are working hard on this and it is quite a challenge to achieve 30% rPP in a packaging of say 100 grams, but we are happy to take on that challenge," Nick concludes.

For more information:

www.lcpackaging.nl

www.lcpackaging.com