Australian fresh produce growers may soon have a new method of treating fruit and vegetables that minimise microbial food safety risks, with promising results from a current project with the potential to greatly improve food safety and reduce postharvest losses.

The New South Wales Department of Primary Industries is leading the project on a postharvest treatment using supercharged air, which has strong potential to improve food safety and decay control outcomes in a range of horticultural products. Food Safety Scientist, Dr SP Singh says microbial contamination is among the greatest challenges for produce growers and packers.

"It is important to have a hurdle approach to minimise the risk of contamination and further reduce the microbial levels in the produce to levels which should not pose public health concerns," Dr Singh said. "Postharvest washing operation is not a complete solution to minimise the microbial hazards associated with the field-grown horticultural commodities."

The project is funded by the Hort Frontiers Health Nutrition and Food Safety Fund, part of the Hort Frontiers strategic partnership initiative developed by Hort Innovation, with co-investment from NSW Department of Primary Industries and contributions from the Australian Government.

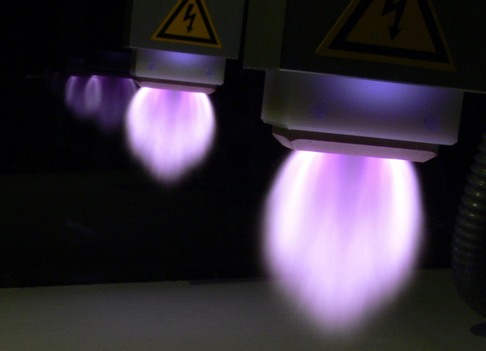

Supercharged air is generated by applying an electric current to normal air which causes the formation of several types of reactive species. Dr Singh says these reactive species interact with microbial pathogens potentially present on the produce surface and kill/deactivate them.

"Washing with water containing a chemical sanitiser is a common practice currently," he said. "The washing processes reduce the microbial load present on the produce surface but do not completely remove if the microbial contaminants are present there. So, it is critical to reducing the microbial levels to the lowest possible by a further auxiliary treatment such as supercharged air. The treatment can also reduce the reliance on the chemical sanitisers and fungicides used to ensure food safety and decay in produce. There is a global push towards zero chemical residues on the horticultural produce. The postharvest treatment with supercharged air has strong potential to achieve sustainability and environmental outcomes."

Dr Singh presented recently delivered a webinar to members from the apple and pear industry, but the research team has experimented with a range of fresh horticultural produce and nuts. Dr Singh points out that the biological and morphological nature of horticultural commodities is diverse, and so is the response to the postharvest treatment with supercharged air.

"At this stage, we can confidentially share that this will be successful in a wide range of products," he said. "The NSW Department of Primary Industries has been working on the development of this technology for over 3 years. After the success of laboratory experiments, the technology is currently in a scale-up stage where the target industries will be involved in the demonstration of the technology benefits and conduct real-world validation studies. There are several stages to go through before the technology becomes available to commercial companies."

He added that the disinfection technologies such as supercharged air have become more important than ever before in the post-COVID era, and consumers want to enjoy healthy, nutritious and safe produce which has been grown, packed and supplied with best practices with minimal impact on the environment.

"Ensuring food safety of produce is a great challenge for growers and packers," Dr Singh said. "The adoption of a postharvest treatment which kills microbes without leaving chemical residues in a short time is the need of the current era. This technology has the potential to improve food safety and enhance produce shelf life contributing to reduced food losses and waste. It is a win-win situation for all supply chain participants to benefit from this treatment technology."

For more information

Dr SP Singh

NSW Department of Primary Industries

Phone: +61 2 4348 1935

sp.singh@dpi.nsw.gov.au