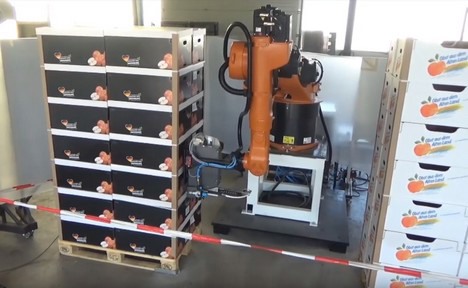

In these times of shortage of skilled workers, machine suppliers are faced with ever newer challenges. Tasks that years ago were still a distant prospect are now becoming important factors in the production process itself or in the logistics of fresh produce. At last year's Fachpack in Nuremberg, the company AKON Robotics showed an application for the automatic labelling of full pallets with adhesive labels. The highly automated solution is so far unique in the industry and is already used in the fruit and vegetable sector, said Thomas Bloch, managing director of Akon.

AKON Robotics, located in Bremen, has its roots in the beverage industry and has been a proven automation specialist in the field of robotics for years. Over the years, however, the North German company has also entered other sectors - such as the egg industry and now also the fruit and vegetable sector. In the course of the high demands placed on modern machine equipment, a highly efficient, high-tech labelling solution was developed. "In plastic crates such as KLT, EuroPool, IFCO or other variants, it is now finally possible with this new version from the AK-Label product series, to label or re-label safely at a later date. We are also able to label cardboard goods on full pallets," Bloch explains.

The robotic solution offers multiple benefits to the respective packaging or fruit trading company, claims Bloch. "Firstly, our application is able to deliver the same high performance continuously. Secondly, the labels must be printed in advance, being glued to the correct crates. We designed our solution so that the robot does not have to pick up the labels from the printer every time, but we have brought the printer to the robot arm. In the end, the application recognizes the crates and sticks the corresponding labels on them."

The AK-Label V2019 system designed and manufactured by AKON Robotics can be individually combined. Thus it can be integrated to the operational requirements as a complete solution or as a stand-alone solution. "Our system counteracts the shortage of employees and a reduction of incorrect labelling is achieved, which in turn significantly reduces recourse claims. The process has already been used in the top fruit, cucumber, potato and onion sectors. But the potential is inexhaustible!“

For more information:

Thomas Bloch

AKON Robotics

Oppenheimer Straße 21

28307 Bremen

Tel.: 0049 (0) 421 32263- 85

Mobile: 0049 (0) 163 73 28 696

Fax: 0049 (0) 421 32263- 71

mail: t.bloch@akon-robotics.de

web: www.akon-robotics.de