A good start of the trade fair week for FibreDust. At the GreenTech this week, they can announce that they have recently been officially admitted as an RHP-certified supplier of BVB Substrates. This means that the coco coir substrate that FibreDust supplies to BVB meets the highest quality standards in the industry.

Coco coir and husk chips

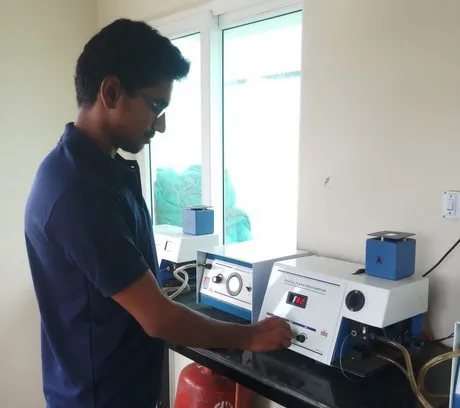

The certified production location is that of Anar Coir, in India. Over there, buffered and washed coco coir and husk chips are produced. In collaboration with BVB and Eldik Business Development, the production location has in recent months been prepared for this. A full quality system has been set up for this production. May 20th was the official day. Together with the certification also the quality assurance has been formalized.

"It's about bringing different cultures together", says Geerten van Eldik from Eldik Business Development, who is involved in the project. "That also means an increasing awareness: in India they don't necessarily know what eventually will happen to the coco and why constant quality is important. For example, investments had already been made in a barium chloride analysis to check the buffering on location, but because of a lack of knowledge, this was not yet sufficiently executed. That is part of the process."

Production processes such as in-house fiberization, the use of installations for reverse osmosis, buffering and washing and the use of the 3-hectare concrete drying floor, the sand separator and their own quality lab were also checked and standardized.

Standardisation

"The standardized working method results in perfect high-air figures, buffering and low ECs," says the FibreDust team. "By sharing the knowledge from BVB and combining it with the manpower, production facilities and the FibreDust laboratory, the quality guarantee that RHP stands for, is now guaranteed to the highest level", the company says. "It is the next step in the supply of high-quality coco raw materials."

Visit FibreDust at Greentech at booth 10.116

For more information

FibreDust LLC

T: +1 860-613-0077

customer.support@fiberdust.com

www.fibredust.com