In today's fresh food industry, the demand for loose goods in tubular bags is rapidly increasing. To meet these requirements, appropriate packaging lines are required. Barsch Maschinenbau, headquartered in Reiskirchen, Germany, has been specializing in the production of modern tubular bag systems for over 30 years and has now succeeded in developing a system with which a wide range of sensitive products can be flexibly packed.

Frank Lindenstruth (r) and Herbert Persch at this year's Fruit Logistica, where the packaging line was presented for the first time.

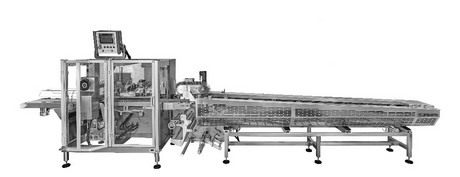

The main advantage of the new model BS BB RP is that you can do without a tray or bowl. Because all products can now be entered loose, to be offered in the trade, explains the technical director Frank Lindenstruth. "Originally the plant was developed for apples, but after its presentation at Fruit Logistica, it is also used, among other things, for packaging carrots." This fulfills several requirements in one go. "You can see the packaged product from all sides, no underlay is needed and the machine is also very gentle on the product."

The main new development was the infeed conveyor for the rolling products. On the main machine, however, only details have been improved, so round and loose products can now be processed. Lindenstruth: "We work with a modular system: In other words, when a new customer contacts us, we configure the system to the extent that it is ideally suited to the respective product."

From apples to herbs

Two years ago, in the wake of increased demand for apples in tubular bags, the first grower cooperatives approached the machine manufacturer. A suitable procedure was sought for the packaging of pome fruit in flowpacks. "The entire development to the presentation at Fruit Logistica took about one and a half years. Originally the installation was intended purely for apples, but it is now also used for packaging carrots and herbs," says Lindenstruth.

The maximum machine output amounts to a cycle number of 80 tubular bags per minute.

Due to the unexpected interest from other product areas, there are endless possibilities and prospects across the fruit and vegetable industry, according to Lindenstruth. "Cooperatives as well as packers and trading companies now see the opportunity to cover a wide range of products with a packaging machine. The use in the carrot area shows us that you can pack 200g snack carrots to a kilo bag without much changes. Even trials with compostable packaging have been successful. We have run a total of 36 different fresh products in the test run and there were no significant problems for any single product. This flexibility -especially for sensitive products- is a great advantage."

'Open it up to more customer groups'

The Barsch company has been developing horizontal flow wrappers for 33 years. The modern systems are delivered to customers throughout Germany and its neighboring countries. "In principle, our installations are suitable for customers along the entire supply chain - from small farms to industrial processors. The next step is to open things up to even more customer groups in the fruit and vegetable sector," concludes Lindenstruth.

For more information:

Barsch GmbH & Co. KG

Frank Lindenstruth

Burkhardfelderstraße 19

35447 Reiskirchen

06408 96947-0

info@barsch.co

www.barsch.co