Most of our working hours at the Horticulture team are clocked during daytime. But did you know that we also regularly put in night shifts? Nighttime is when we measure if the LED lighting installed gives off the light intensity we calculated. But why at night?

by Leontiene van Genuchten and Rachid Allaoui

It’s important for growers to make sure that every plant in the greenhouse is grown under the same optimal conditions. Irrigation, fertilization, crop care and lighting – all have to be set up to produce consistent, high quality results. At the Horticulture team, we go to great lengths to ensure that our light plans for LED grow lights fit the exact needs of the grower and the actual conditions of their greenhouse.

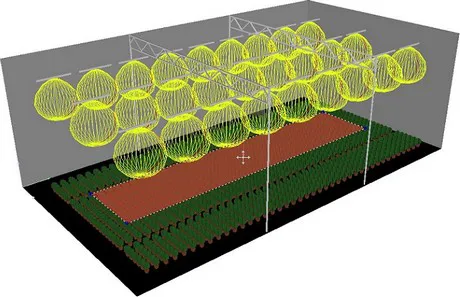

Our light plan is created based on a computer simulated greenhouse, which calculates the number of light photons (µmol) that will fall on a given area (square meter), every second. Every greenhouse is different, so every light plan is unique. Think about different structures, crops and screen systems.

Figure 1. Simulation of a section of a greenhouse. The central area (shown in red) is positioned at virtually the same height as the crop. The yellow lines represent the light distribution of the LED modules.

Having a light plan on paper is one thing, but we measure LED lighting in the actual situation to make sure that the light level calculated is achieved on a consistent basis. For our LED lighting projects, we use a spectroradiometer or a PAR (Photosynthetic Active Radiation) sensor that shows the light measurement in µmol/s/m², to take periodic measurements of the average light level in the greenhouse. This is the only accurate way to measure the amount of light that the plant uses. In contrast, a lux meter measures the light intensity as perceived by the human eye, in luminous flux/m². Our eyes are most sensitive to green light, but red and blue light are the most effective colors to maximize photosynthesis in plants so those are the ones you want to measure.

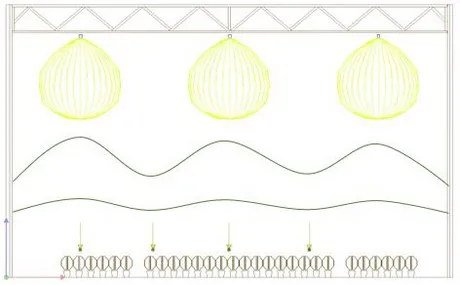

The light level in µmol/s/m² that can be achieved for a given area (m²) depends on the number of LED modules installed, the output (µmol/s) of the installed modules and nearby reflection surfaces. When we perform measurements, we measure the light level both at the position directly under the LED modules as well as the position between the LED modules. We do this to calculate a correct average light level. Figure 2 shows these two measurement positions as small green dots. The closer you are to the module, the higher the light intensity. The light intensity goes down as you go farther away, because the light coming out of the module is spread over a larger area. The measurement positions and distance between the light sensor and the LED modules, are the key factors for obtaining accurate measurements. Measurements also have to be taken at the correct height in the greenhouse to ensure that the light beam is optimal and uniform at the top of the plant. Measurements could be performed at various heights to determine an optimal uniformity. The uniformity increases if the difference between the maxima and minima of the green curves in Figure 2 decreases.

Figure 2. Front side view of the greenhouse. The small green circles indicate the measurement positions. Notice that the same distance is maintained between the measurement positions. The average light intensity goes up if you only take measurements directly under the LED modules.

We measure the light level at several pre-determined positions, and then compare these with the simulated amounts given for the same positions in the light plan. This allows us to confirm that the levels specified in the light plan are actually being achieved.

So why the night shift? Sunlight disturbs the measurements, so we would be measuring both the light output of the LED lights and the amount of daylight during daytime. That’s why we have to do our light measurements before sunrise or after sunset to measure the amount of light produced by the lighting system alone.

Figure 3. I’m standing with a stand that holds a spectroradiometer used to take measurements without daylight.

It is always an extraordinary experience to be in a greenhouse at night surrounded by pink LED lighting with nobody around and no music playing. We sometimes use a measurement stand to hold the light sensor up and away from our body to avoid casting a shadow over it and to reach taller crops.

The results of our light measurements are put in a report that we share with the grower. It describes the measurement conditions, e.g. the distance between the LED module and light sensor, the use of screens, crop height, number and position of measurement points, the average light level and light uniformity. A light measurement can be repeated to determine if the correct light level was achieved.

Note: Light measurements of the specific output and lifetime of LED modules are carried out in optical laboratories under standard conditions specified by international norms. It is impossible to reproduce these conditions in a greenhouse.

Signify

Signify