How to inject nutrients and water treatment additives into systems controlled by sophisticated irrigation controllers? That was something Jeff Smith with Dema wondered a couple of years ago. "The goals; easy to install on any existing system, easy to maintain, surviving not just fertilizers but also a wide range of chemicals, any AC voltage between 100 and 250 volts, 50 or 60 hertz and 12 VDC for remote locations. And of course it must be cost effective!" The Easy Dose is the result.

Jeff started his research back in 2010. "During visits to greenhouses and farms, I was seeing systems that monitored everything, EC, pH, soil moisture, humidity, sunlight, hours of total darkness and even ORP for controlling bacteria in the irrigation water. By 2012 I had developed a list of questions and started asking the companies that make these systems. Some were very helpful, others thought we were going to copy their controllers."

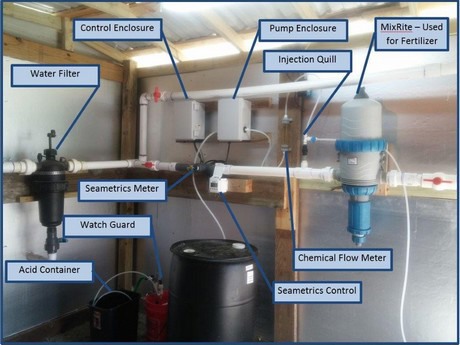

He concluded that the pumping systems are not always easy to use, not easy to add to an existing system, expensive in many ways and not easy to maintain. "Most did not even provide a simple way for the grower to actually see how much product was being injected. After 7 months of asking questions and not seeing a cost effective solution I wrote a 14 page document laying out what people told me, and suggesting options. Through several meetings we came to a better understanding of what we should do and at that point we went back to some of the companies that had helped us and offered working prototypes when they were ready."

Dema started working on a system of their own. "The goals; easy to install on any existing system, easy to maintain, surviving not just fertilizers but also a wide range of chemicals, any AC voltage between 100 and 250 volts, 50 or 60 hertz and 12 VDC for remote locations. And of course it must be cost effective."

The Easy Dose is the result of numerous conversations with growers, manufacturers of integrated systems for greenhouses and companies tired of existing pumping systems.

"During the prototyping phase we learned the ability to inject a second additive independently of the fertilizer would help the growers, so we added a second channel to the circuit board to drive a second pump", Jeff shows. "The uses for Easy Dose units literally doubled by adding this feature."

Once they had introduced the Easy Dose, the next customer request was, if they could monitor and control pH with an easy to install pump, which could be added to any system and would be cost effective. "This request led us to introducing the Flex Flow Acid pump which has a pH probe and automatically injects any kind of acid to adjust the pH of water and treat the soil that the water contacts. Since the vast majority of plants grown for food thrive in soil and water that has a pH below 7, the 0960. A Flex Flow has become a very popular tool", Jeff concludes.

For more information: DEMA

DEMA

Matt Brandt, Industrial Products & AG Division Sales Manager

mattb@demaeng.com

Jeff Smith, Retired VP of Sales for Strategic Markets

jeffs@demaeng.com