The energy transition is in full swing. More and more electricity is generated from sustainable sources. A good development that is also accompanied by an increase in fluctuations on the grid and thus with more uncertainty about the supply of electricity. Just add the ever increasing electricity prices to this and it soon becomes clear that in the current market the role of the CHP is far from over. Generating electricity yourself is again becoming even more appealing. Dennis van Leeuwen of MAN Rollo, supplier of diesel and gas engines: "Nobody knows exactly what the position of the energy transition in ten years time will look like. Until then, investing in a CHP is beneficial, because in many cases within three to four years you have already earned your investment back and then you will still benefit from it for years."

The energy transition is in full swing. More and more electricity is generated from sustainable sources. A good development that is also accompanied by an increase in fluctuations on the grid and thus with more uncertainty about the supply of electricity. Just add the ever increasing electricity prices to this and it soon becomes clear that in the current market the role of the CHP is far from over. Generating electricity yourself is again becoming even more appealing. Dennis van Leeuwen of MAN Rollo, supplier of diesel and gas engines: "Nobody knows exactly what the position of the energy transition in ten years time will look like. Until then, investing in a CHP is beneficial, because in many cases within three to four years you have already earned your investment back and then you will still benefit from it for years."

The greenhouse horticulture sector is currently characterized by scaling up and the increasing growth of individual companies. Nevertheless, there are still very many companies of smaller size that need more and more electricity as a result of modern cultivation developments. It is precisely for these companies, with an electricity demand of up to 1 megawatt, that Dennis sees opportunities. "Many smaller companies now fall between two stools. They do need electricity, but do not opt for a flue gas purifier from a cost point of view. With a CHP up to 1 megawatt, such a flue gas purifier is not necessary, because the current smaller CHPs nowadays comply with the strictest emission requirements even without such a device. In the past, these types of installations were a no-go because they were not as efficient as a large CHP, but that is now a thing of the past."

Own emergency power supply and favorable earnings model

With an own CHP, growers can generate electricity themselves, making them no longer dependent on the supply of electricity from the grid. Certainly in view of developments in Belgium, where there is fear of a black-out whereby the power on the grid is disrupted, it is important to be able to guarantee a good climate for the crop. And because many European electricity grids are nowadays connected, the neighboring countries will also notice some effect of this. "Growers with a CHP have their own emergency power supply."

But an own CHP does not necessarily mean that growers can no longer take electricity off the grid. "It is rather the case that growers can choose themselves. If the grid power is cheap, grid electricity can still be favorable, if the prices are high, delivery to the grid will yield an interesting earning model. At times when the CHP is not needed, it can supply back and stabilize the grid. This is very interesting for Tennet in connection with the fast up and down switching. But recently, balancing on frequency is also possible. Suppose a grower is running a CHP of 1 megawatt at full power, but requires only 90 percent of that power. With this, the grower generates his basic load and, for example, 10 per cent of adjustable power is left over. This allows a grower to sell his frequency control (R1) at an even more appealing price."

Stimulation of CHPs pure necessity

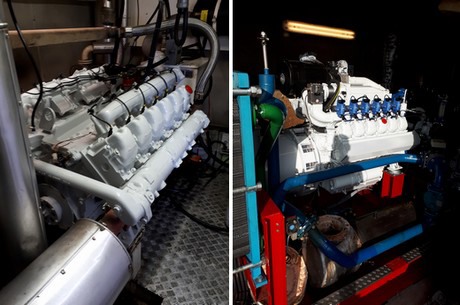

By the way, not only smaller companies can benefit from CHPs with a lower capacity. Also the combination of several smaller installations instead of one large one has advantages (redundancy and efficiency retention in partial load). "Smaller installations are also used in the automotive and marine industries. As a result, the purchase costs are lower and also the maintenance is cheaper. The parts are more readily available and the grower is not dependent on just one supplier."

MAN Rollo, part of the Pon Group, is active in nine European countries. "The Netherlands is densely populated with CHPs, so in terms of capacity, we should be able to do very well. It is mainly about setting off the short-lived dips, the ripples between the quarters. The situation is particularly serious in Belgium, where stimulating of CHPs is now really a necessity", Dennis concludes.

For more information:

MAN Rollo

www.manrollo.com

info@manrollo.com

Dennis van Leeuwen

d.vanleeuwen@manrollo.com