The Time Scale project is a continuation of an existing program researching plant growth in space with the objective of preparing for long manned missions to Mars, for example. The Time Scale project is to understand how plants grow in different gravities, i.e. Mars, Moon, lower earth orbit, etc.

The acronym TIME SCALE refers to the project title Technology and Innovation for development of Modular Equipment in SCalable Advanced Life support systems for space Explorations. The project involves eight consortium partners from six European countries, including small and medium sized enterprises and universities. This cooperation is complemented by a Scientific Advisory Board (SAB) with members from USA, Canada, Germany, Norway, and Sweden.

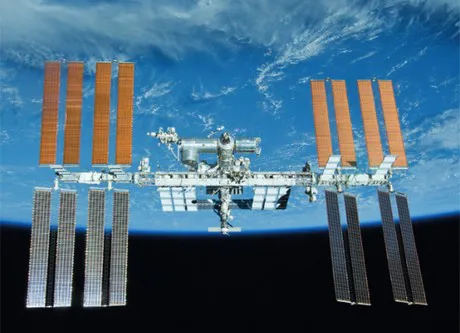

Food production and life support systems are crucial for future long term missions in space. The International Space Station is site for scientific experiments and technology demonstrations. Photo: NASA

Feeding astronauts

Advanced plant cultivation systems may in the future provide astronauts with space-grown food and regenerative life support systems that recycle water, nutrients, air and waste. Such systems will be important for future long term missions in space. The Time Scale project will develop an advanced life support system concept to allow life science research and technology demonstrations under different gravity conditions. This will contribute to closed regenerative life support systems for future space exploration.

Dr. Ann-Iren Kittang Jost is project coordinator at the Centre for Interdisciplinary Research in Space, which is part of NTNU Social Research (a non-profit research company owned by the Norwegian University of Science and Technology), and one of the scientists involved in the Time Scale project. During her master studies, she was invited into a research team preparing an experiment to investigate the impact of weightlessness on plant cell walls as part of a space mission in 1996 with the European Space Agency. According to Ann-Iren, the benefit of plant cultivation research is more into the future. "Currently we are doing fundamental research and technology demonstration on the International Space Station (ISS). The astronauts are doing a fantastic job performing experiments and technology demonstrations. Today the astronauts bring with them the supplies they need from Earth, however, in the future they will benefit from our research growing their own crops providing them food, oxygen and pure water."

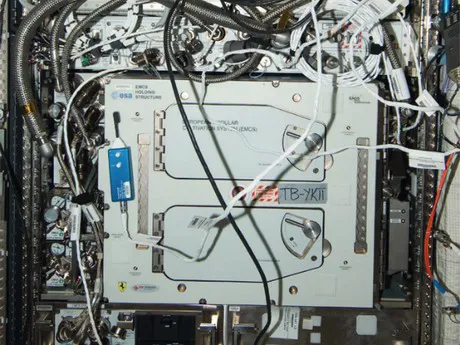

The European Modular Cultivation System (EMCS) on board the ISS. Inside, spinning rotors allow life science research under various gravitational conditions, e.g. to simulate Martian and Lunar gravity. Photo: NASA.

EMCS

Time Scale is based on an experimental "greenhouse" system onboard the International Space Station (ISS). This European Modular Cultivation System (EMCS) has been successfully operated on ISS since 2006. Leo Marcelis and Sander van Delden of Wageningen University are also involved in the Time Scale project. They explain what the system does: "In this system, cultivation chambers on spinning rotors allow life science research under various gravitational conditions, e.g. microgravity and simulation of martian and lunar gravity. The EMCS modular design allows replacing and upgrading individual subsystems. Time Scale aims at improving EMCS technology to conduct a new generation of advanced life science experiments in space."

SIFT-MS

Another scientist involved in the Time Scale project is Dominique Van Der Straeten of Ghent University. Together with colleagues at the university's Laboratory of Functional Plant Biology, she worked on non-invasive technology (through image analysis and analysis of volatile compounds) which allows detection of infections, nutrient shortages and other types of stress at an early stage.

This technology was developed in the lab in Ghent, in conjunction with Joeri Vercammen of InterScience Belgium. As part of the Time Scale project, Van Der Straeten and Vercammen looked into miniaturization of the imaging technology, as well as the use of SIFT-MS technology and gas chromatography for the analysis of volatile signaling molecules.

Earthly benefits

It's nice to know astronauts will soon be able to grow their own crops in space, but what about all those growers here on earth? How will they benefit? Ann-Iren identifies three areas of benefit:

- Fundamental knowledge: "Cultivating plants in space is a unique way to gain fundamentally knowledge of how living organisms respond to environmental factors. Gravity is one of many factors or stimuli that plants are exposed to and the plants use the gravity vector as a reference during growth and development on Earth. We take it for granted because it has been there during evolution and is there constantly. To illustrate the benefits for growers long term I will give an example: By growing plants under weightlessness we learn how gravity affect plant response to other stimulus such as light, and light is important for cultivation also on Earth to maximise yield. When we understand the different response mechanisms to various environmental factors, we can use it to improve crop species on Earth and better predict and optimise cultivation."

- Closed loop systems: "For long duration travelling in space astronauts have to produce their own supplies such as food, oxygen and water using regenerative life support systems. Plants are foreseen to have a key role in such systems. These systems have to be closed: recycling and reusing resources such as water, nutrients, air and none-edible bi-products/waste. Sustainable food production systems are required also on Earth because our resources are limited (e.g. phosphorus) and we have to aim for a zero waste emission to the environment. Waste from one production system must become a resource either within the same system or in another production system."

- Technology innovation: "Although the scale/volumes of crop cultivation in space and on Earth are very different, there is a large technology transfer potential to growers on Earth. Closing and recycling cultivation systems requires new concepts and technology of monitoring and control."

One of the biggest eye-openers gained from the project, Leo and Sander tell us, was the low amounts of nitrogen that lettuce plants can grow on. If lettuce is cultivated directly in nutrient solution (no substrate) all N is available for the plants. If the EC is high enough (e.g. using Chlorine and sulphate instead of NO3) plants can survive on very low dosis of N (1 to 2 mmol/L). "This potentially has advantages in terms of environmental impact (lower emissions when nutrient solution is discarded) and potential suppression of plant diseases. Using low N concentrations the plant can still be firmer and still grow optimally, but growers have to realise, of course, that there should be a continuous supply of N because the lettuce will need to have around 5% nitrogen of the dry matter to have optimal growth. That absolute amount of nitrogen should be available but the concentration in which its fed to the plants can be almost 10 times lower."

In the model plant arabidopsis they found that traditional nutrient solutions that are used by researchers are often too strong, and plants can grow optimally on much lower EC values. This is plant-specific, however, and is not true for all plants.

And there are the findings of using the equipment (SIFT-MS of interscience and CleanGrow ionspecific sensors) that can gain better insight in plant-plant and plant-environment interactions. Also the usage of special cameras (heat and fluorescence) has the potential to get fundamental insight, but also practical knowledge on how "stressed" plants are.

Today’s Experiment Container of the EMCS. The TIME SCALE project will develop improved cultivation system concepts and technology for next-level life science experiments. Photo: NTNU Social Research.

In practice

Leo and Sander point out that the EMCS 'electronic nose' technology has obvious transfer potentials from space research to terrestrial applications: "Large-scale industry greenhouses may in the future use such systems to monitor plant health and continuously optimize the growth conditions, improving production yield and product quality."

And while the main goal is to upgrade the existing EMCS rotors that are onboard of the ISS today, they developed a fully automated miniature greenhouse that has real-time monitoring of nutrient solution composition and recycling of nutrient in a closed water loop. "This miniature greenhouse is placed on a rotor that can be placed in the ISS and then mimic zero gravity up to 2 times earth gravity. The ion specific sensors are miniaturized and are now only a few mm thick. The whole nutrient system fits in a box that is smaller than a shoebox. The system has a touch screen interface and can be operated from any smartphone on any place where there is internet connection. The system has obvious potential for greenhouses on earth."

The SIFT-MS and CleanGrow sensors are already being used in pilot tests in commercial greenhouses, while the insights for better nutrient solution for arabidopsis are adopted by researchers.

Roy O'Mahony, who is involved with the Time Scale project through his company, CleanGrow, adds that the project mainly has benefits for producers who grow without soil. "They have to be very careful that the drip solution going to the plants is correct for all the nutrients a plant needs in the right ration. All growers recycle the unused drain solution, this must go back to a collection tank and needs to be measured so it can be adjusted and reformulated to go back out to the crop." Growers now send samples to labs. "In the Netherlands you have an amazing network of labs with fast turn around times," Roy says, but outside of the Netherlands it is not so efficient and can take 5 days or more. "Even in the Netherlands growers would like to have real time data, even if it is for the macro elements NPK, Ca, etc."

For more information:

TIME SCALE

TIME SCALEtimescale.eu